For food process & bakery equipment, industrial oven, industrial furnaces, glass, ceramics & metal casting facilities, etc

Hello! Welcome to Wheelsway. This page provides an overview of our high-temp resistant casters, including what they are, where they are used, and key technical specifications. If you need additional details or have specific requirements, feel free to contact us to discuss your application.

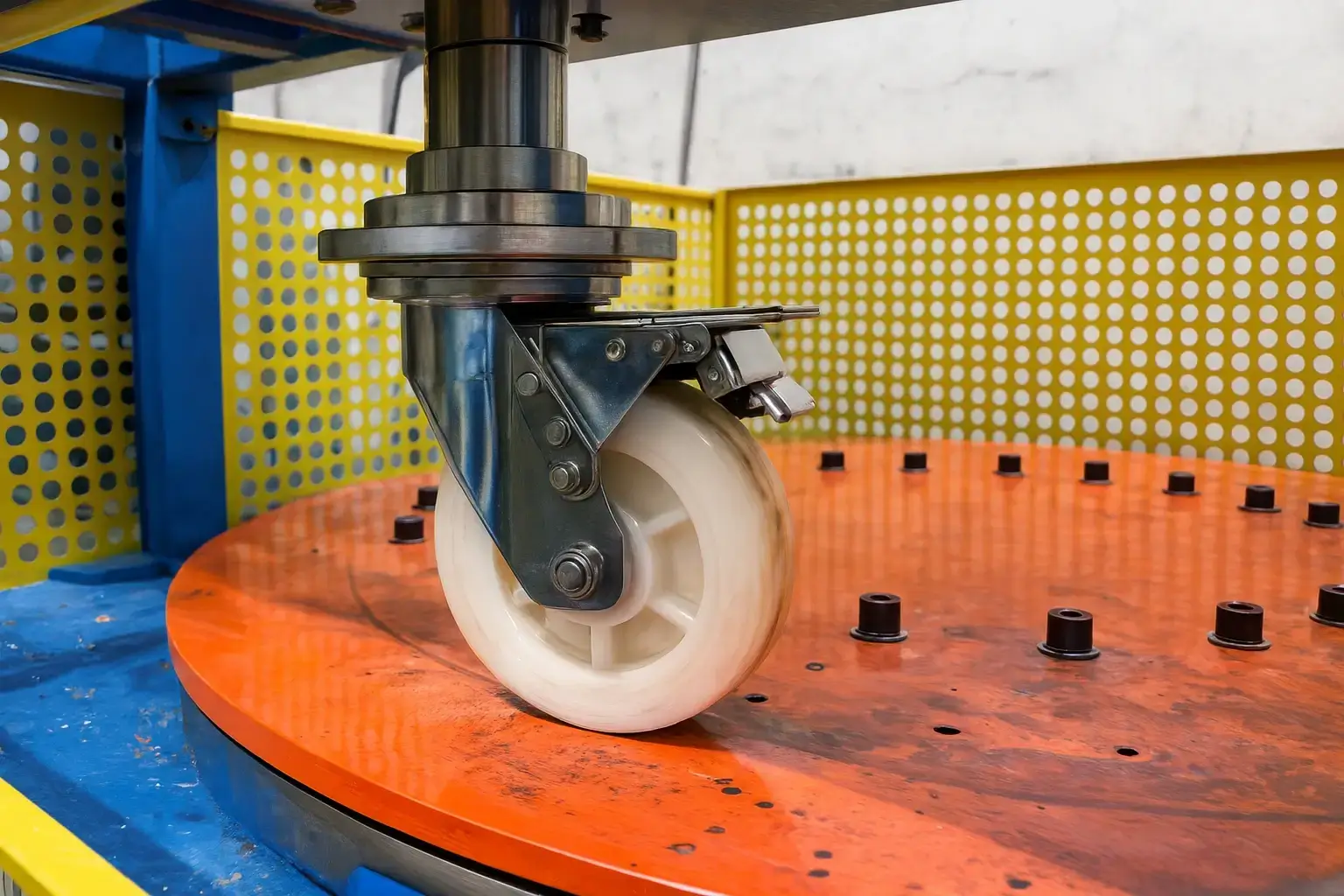

High‑temperature resistant casters are casters specifically designed so their wheels, bearings, and brackets can operate safely and repeatedly in high‑heat environments (such as ovens, autoclaves, bakeries, powder‑coating lines, or furnaces) without deforming, softening, or seizing.

High‑temp wheels keep their hardness and strength at elevated temperatures, so they do not melt, warp, or “flat‑spot” like standard rubber or PU wheels.

By preventing wheel failure, sudden seizure, or bracket deformation in high heat, they reduce the risk of accidents (tipped racks, dropped loads) and keep production, baking, sterilization, and coating processes running without caster‑related stoppages.

These casters suffer less thermal damage, cracking, or grease breakdown, which extends service life and reduces replacement frequency.

High-temp resistant caster for food processing, autoclaves, glass manufacturing, industrial kitchens and chemical facilities, etc

24~72 hours salt spray test passed

1,000 hours salt spray test passed

75mm, 100mm, 125mm

Bearing options: ball bearings(with wheel cap and bushing) / plain bushing; high-temp resistant grease

Bearing options: ball bearings(with wheel cap and bushing) / plain bushing; high-temp resistant grease

Bearing: plain bushing; high-temp resistant grease

Bearing: ball bearings; high-temp resistant grease

80KG~150KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

24~72 hours salt spray test passed

1,000 hours salt spray test passed

100mm, 125mm, 150mm, 200mm

Bearing: ball bearings; high-temp resistant grease

Bearing: ball bearings; high-temp resistant grease

Bearing options: ball bearings, roller bearing; high-temp resistant grease

250KG~400KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

24~72 hours salt spray test passed

1,000 hours salt spray test passed

80mm, 100mm, 125mm

Bearing options: ball bearings(with wheel cap and bushing) / plain bushing; high-temp resistant grease

Bearing options: ball bearings(with wheel cap and bushing) / plain bushing; high-temp resistant grease

Bearing: plain bushing; high-temp resistant grease

Bearing: ball bearings; high-temp resistant grease

Bearing: ball bearings; high-temp resistant grease

90KG~150KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

| Material | Glass fiber filled Nylon | Phenolic Resin | Silicone | Epoxy resin |

|---|---|---|---|---|

| Tempreture Resistant |

Up to 280°C |

Phenolic: up to 180°C. Phenolic resin:280°C. Phenolic resin with glass fiber: 300°C |

Designed for continuous use up to about 280°C |

Designed for continuous use up to about 280°C |

| Floor Protection |

Hard, non‑marking but relatively aggressive; suitable for smooth, hard industrial floors, not ideal for delicate or soft floors. |

Very hard, non‑marking but harsh on floors; can cause increased wear or damage on poor/soft floors. |

Soft, non‑marking and highly floor‑protective; suited to delicate or finished floors even at high temperature. |

Non‑marking floor protection |

| Noise in movement |

Hard tread. Medium to high noise, especially on hard floors; vibration and impacts transmit clearly. |

Typically the loudest. Very hard wheel running on hard surfaces produces high rolling noise. |

Quietest option. Elastic silicone tread provides low‑noise, smooth running. |

Typically louder on hard floors. |

| When to choose |

High loads on smooth/hard floors (concrete, tile. Wet/chemical exposure (steam cleaning, smokehouses) Floor marking not critical. |

Heavy loads on smooth concrete. Continuous dry heat. Oil/grease/chemical resistance needed Cost-sensitive industrial use. |

High heat + cushioned ride, floor protection critical (epoxy, tile, finished floors) Low noise operation essential. Food/pharma hygienic environments. |

Choose for hot + wet/steam/chemical exposure (bakeries, food processing plants, autoclaves, labs) where you need non‑rusting and non‑marking behavior at high temperature. |

| Ideal for |

Food‑processing plants, pharmaceutical labs, industrial kitchens and chemical facilities |

Bakery ovens, autoclaves and dry curing |

Cushioning and floor protection in high‑temperature environments |

Bakeries, food processing plants, autoclaves, labs. |

EN 12527 is the foundational European standard that defines how to test the performance of caster wheels and castors. It specifies in detail the test methods and apparatus used to evaluate factors like strength, durability, and safety. (standards.iteh.ai). This standard itself does not set the pass/fail values for every caster type; instead, it provides general procedures. Specific acceptance criteria for different caster categories (furniture, medical, industrial, etc.) are given in the respective specialized standards

EN 12532 addresses transport castors and wheels intended for industrial applications where equipment is moved at speeds up to 1.1 m/s (4 km/h). This is roughly a fast walking speed, indicating the standard is for carts or trolleys that might be pushed or towed slowly in warehouses or factories. The standard lays out technical requirements, dimensions, and testing for casters used on non-powered or hand-towed industrial transport equipment. EN 12532 explicitly excludes certain categories: it does not apply to furniture or office chair casters, institutional or hospital bed casters, or any powered/driven equipment casters. Those excluded categories are covered by other standards (e.g., furniture by EN 12528/12529, hospital by EN 12531, and higher-speed driven equipment by EN 12533). Essentially, EN 12532 is focused on wheels and castors for manually propelled or tugged industrial carts and platform trucks operating at low speeds.

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

High‑temp resistant casters are built from heat‑resistant materials—such as glass fiber filled Nylon, phenolic resin, silicone, steel or cast iron—that resist softening, deformation and breakage under extreme heat. Standard rubber or plastic wheels can melt or crack under heat.

Yes. Phenolic wheels are chemically resistant and durable, so they are suitable for food‑processing facilities; however, for direct food contact, food‑grade silicone casters may be preferable

Yes. Silicone heat‑resistant casters are designed for durability and flexibility. They can withstand temperatures up to 250 °C and are suitable where a softer tread is beneficial

Yes. Most high‑temperature casters—especially those with steel or cast‑iron wheels—are engineered to carry heavy loads without compromising performance.

Yes. We can tailor dimensions, materials and load capacities to meet your unique requirements. Customisation might include special wheel compounds or bearing types.

They eliminate issues such as melting or deformation of standard wheels, reduced mobility due to thermal expansion, frequent wheel replacements, poor maneuverability and floor damage. Heat‑resistant materials retain shape and allow smooth rolling, reducing downtime.

Yes. Models with non‑marking, chemical‑resistant treads are ideal for food production areas, where sanitation and floor protection are critical

Absolutely. High‑temperature swivel casters retain 360° rotation and flexible movement even in high‑temperature zones, making them essential for maneuvering equipment in confined spaces

Lifespan depends on load and environment, but with proper maintenance—including routine inspections, lubricating with high‑temperature grease, staying within weight limits and cleaning after use—heat‑resistant casters last significantly longer than standard wheels

we are just one click away

*We respect your privacy and all your information are protected.