We supply casters with capacities from 20kg to 35,000kg for all industries.

We had rich factory based experience working with distributors, MROs, OEMs, etc, which gave us deep insight into what customers value most and where traditional suppliers often fall short.

Practical knowledge of compliance standards such as EN12530, EN1004, OSHA, ASTM, RoHS, and REACH.

Proven understanding of common customer challenges: quality drift, long lead times, and high ownership costs.

Enjoy free caster samples in just 2–3 days and production lead-time within 20 to 30 days.

We welcome small orders to start our partnership, offering personalized service and collaboration from day one.

We address and resolve issues promptly to keep your operations running smoothly.

With Wheelsway, you work with one responsible partner who ensures stable quality, transparent issue handling, clear communication, and keeps your projects and sales plans on track.

From standard to production

Strictly controled

always consisten

Sample Speed

Instead of operating a single factory, we work through a dedicated network of specialized caster manufacturers mainly in one city in China.

Each partner factory is selected based on product focus, process capability, and quality control — allowing us to match the right manufacturing setup to each application.

For our customers, this means you communicate with one partner, while production is executed by the most suitable factory behind the scenes.

We take full responsibility for:

Manufacturing results are accountable to us — not passed between multiple parties.

This structured production and testing approach ensures you receive the same performance, batch after batch — without unexpected surprises.

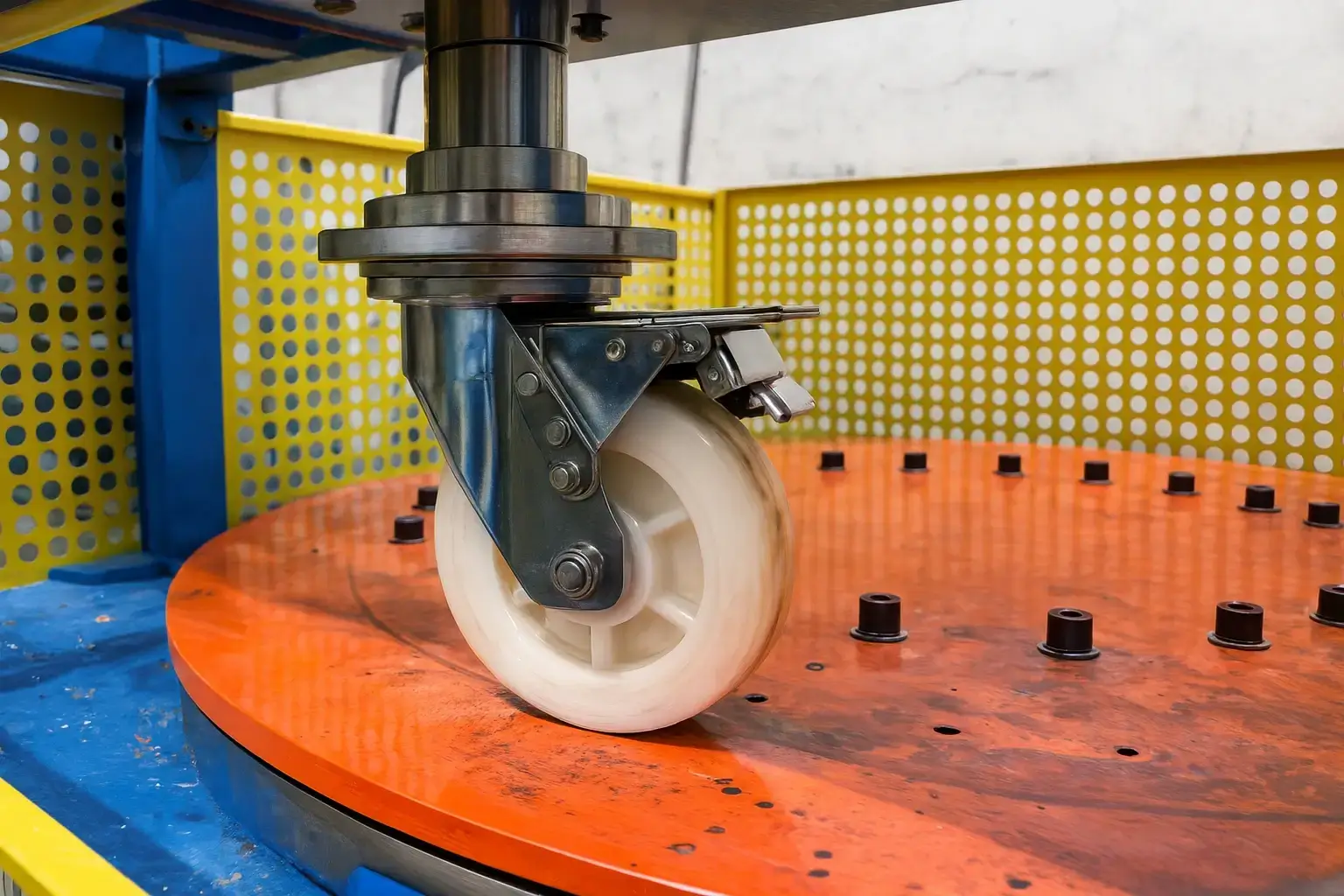

Precise injection molding guarantees uniform material density, stable hardness, and consistent wheel dimensions across every production batch.

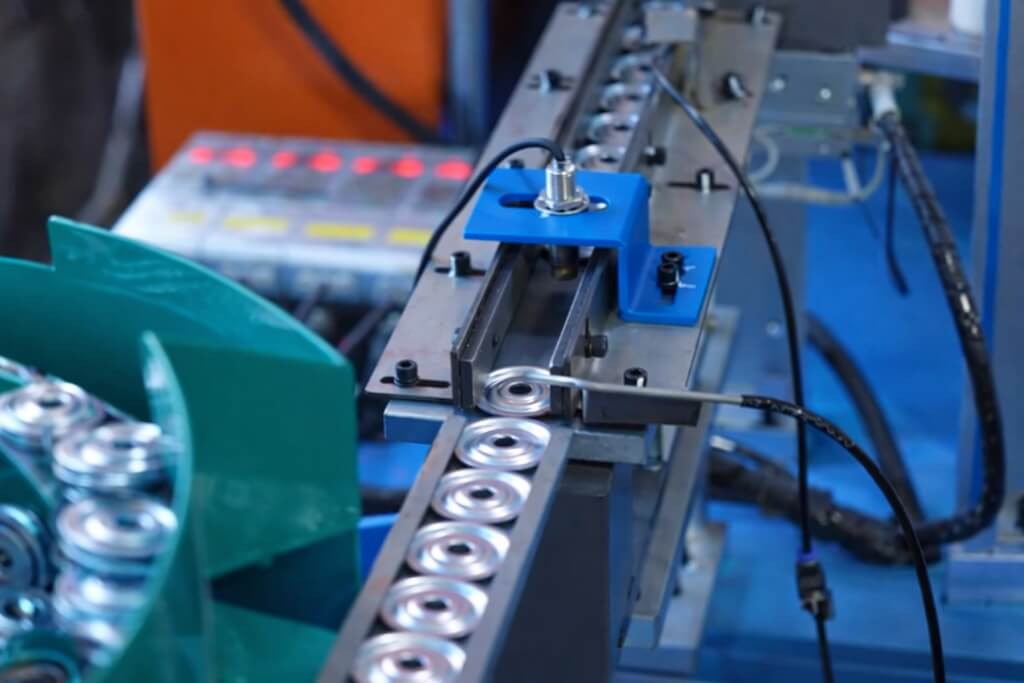

From raw material verification to final assembly, each stage includes dimensional checks, surface inspection, and functional validation to ensure every unit meets specification.

Casters undergo dynamic load and rolling performance tests according to international standard to verify durability, stability, and long-term reliability.

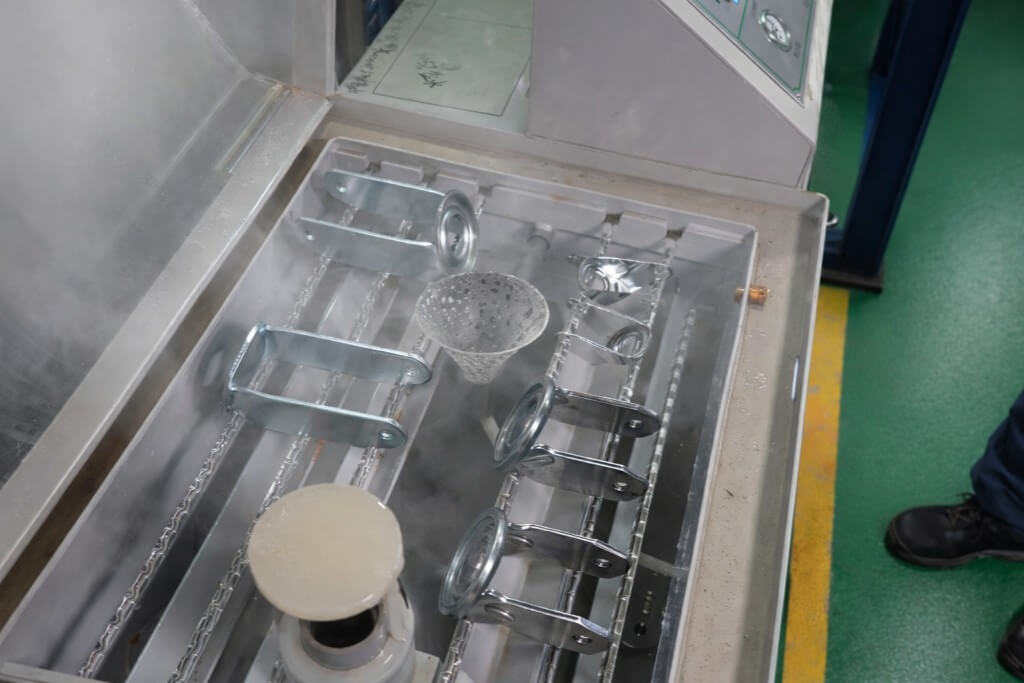

Corrosion resistance is evaluated through salt spray testing to assess surface treatment durability and long-term performance in humid or aggressive environments.

Precision stamping and forming ensure structural strength, dimensional accuracy, and stable load-bearing performance from the very first production stage.

Standardized assembly procedures and controlled setups ensure consistent specifications, secure fastening, and smooth swivel or rolling performance.

We are ready to assist you seamlessly from start to finish!

eric@wheelswaycaster.com

+86-18148886224

Let’s talk and get a detailed quotation for you. We respect your IP and sign NDAs.