From CNC machines to aircraft platforms and steel coil carts, precision and heavy-duty equipment keeps industries running at full strength. Whether it’s stabilizing sensitive instruments or supporting massive industrial loads, at WheelsWay we connect you with casters built for reliability, strength, and control. Heavy loads, precise moves — we’ve got the wheels to keep it rolling.

Stage equipment castors are specialized casters or wheel assemblies designed to provide mobility and ease of movement for various stage-related equipment. These components play a crucial role in the entertainment industry, allowing for the seamless transport and positioning of stage equipment such as flight cases, mobile stages, backstage equipment carts, light stands, sound systems, scenery, and other essential elements of a performance.

We provide solutions tailored to the demands of modern supply chains. Discover our full range of casters and wheels for logistics and material handling—engineered to keep your operations moving with efficiency and reliability, and explore the key features below and see how our products can power your equipment and streamline your workflow.

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

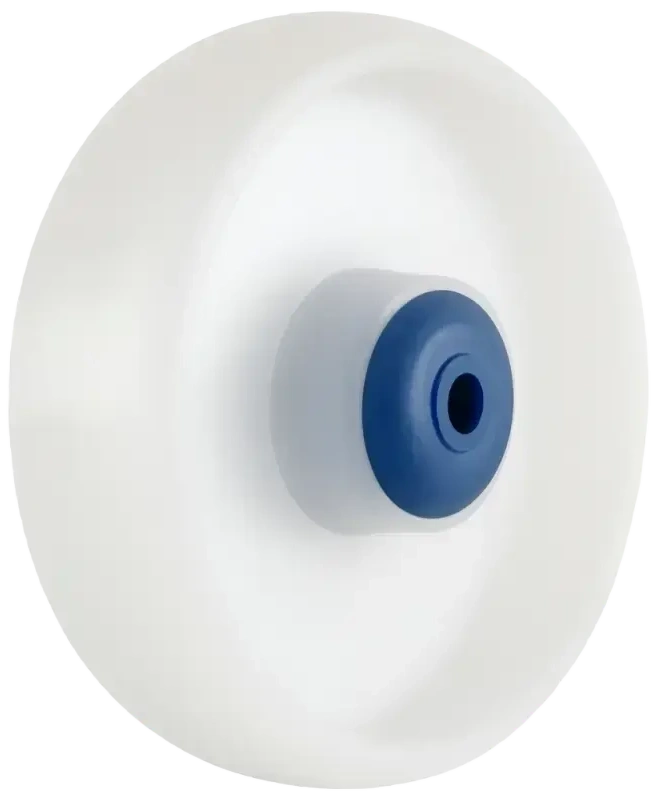

Casters and wheels for precison manufacuring, semi conductive equipment, labtory equipment, precision medical equipment

24~72 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

75mm~125mm

Bearing options: Double ball bearings

Bearing option: Double ball bearings

Bearing options: Single ball bearing

Bearing options: Double ball bearings

Up to 150KGs

24~72 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

80mm~200mm

Bearing options: Plain bushing / Roller bearing / Single ball bearing (can withstand -30℃)

Bearing: Plain bushing

Bearing: Roller bearing

Bearing options: Roller bearing / Ball bearing

Bearing: Double ball bearings

Bearing options: Single ball bearing

Up to 300KGs

24~72 hours salt spray test passed

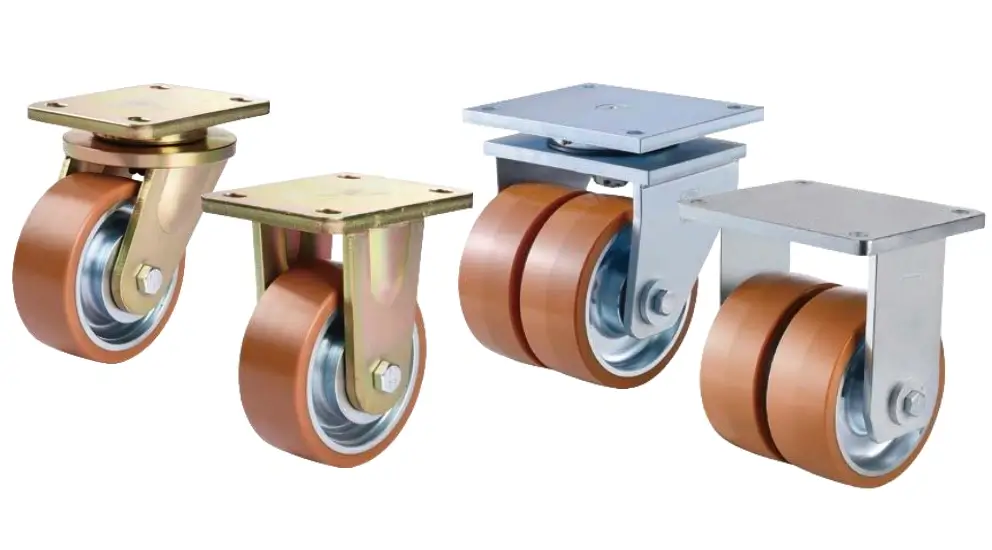

100mm~360mm

Bearing: Double ball bearings

Up to 8,000KGs

EN 12527 is the foundational European standard that defines how to test the performance of caster wheels and castors. It specifies in detail the test methods and apparatus used to evaluate factors like strength, durability, and safety. (standards.iteh.ai). This standard itself does not set the pass/fail values for every caster type; instead, it provides general procedures. Specific acceptance criteria for different caster categories (furniture, medical, industrial, etc.) are given in the respective specialized standards

EN 12530 specifies the technical requirements, dimensions, and testing criteria for castors and wheels used in manually propelled institutional applications. This standard covers medium-duty equipment castors found in public and institutional facilities such as shops, restaurants, hotels, schools, and hospitals. Castors under EN 12530 may include features like wheel brakes or swivel locks, as these are common in carts and equipment used in such environments. The standard ensures that these casters meet appropriate safety and performance levels for frequent manual handling in public spaces

EN 12531 is a dedicated standard for hospital bed casters, reflecting the specialized requirements of medical beds. It specifies the technical requirements, standard dimensions, and testing conditions for swivel castors used on hospital beds. This standard applies to hospital bed castors that are typically larger in diameter (100 mm or above) and equipped with a central locking mechanism. In practice, central locking allows a set of casters to be locked or unlocked simultaneously for patient safety and ease of movement. The scope of EN 12531 primarily covers swivel casters in this medical context, ensuring they meet strict safety and performance needs.

EN 12532 addresses transport castors and wheels intended for industrial applications where equipment is moved at speeds up to 1.1 m/s (4 km/h). This is roughly a fast walking speed, indicating the standard is for carts or trolleys that might be pushed or towed slowly in warehouses or factories. The standard lays out technical requirements, dimensions, and testing for casters used on non-powered or hand-towed industrial transport equipment. EN 12532 explicitly excludes certain categories: it does not apply to furniture or office chair casters, institutional or hospital bed casters, or any powered/driven equipment casters. Those excluded categories are covered by other standards (e.g., furniture by EN 12528/12529, hospital by EN 12531, and higher-speed driven equipment by EN 12533). Essentially, EN 12532 is focused on wheels and castors for manually propelled or tugged industrial carts and platform trucks operating at low speeds.

EN 12533 is the standard for heavy-duty castors and wheels used in applications where travel speeds are higher than walking pace – specifically over 1.1 m/s (4 km/h) and up to 4.4 m/s (16 km/h). It covers castors (including any accessories like brakes) designed for mechanical or power-driven applications in this speed range. This means equipment that is either powered or towed by a vehicle, moving at moderate running speeds. EN 12533 represents the upper end of caster usage, where significant dynamic forces occur due to higher speeds. The standard sets out technical specs, dimensions, and required tests to ensure safety and performance at these speeds. Importantly, EN 12533 excludes certain wheel types: pneumatic-tyred wheels (inflatable wheels) and dedicated drive wheels are not covered, as those may fall under other vehicle or machinery standards.

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

*We respect your privacy and all your information are protected.