这是示例文本,单击 “编辑” 按钮更改此文本。

Hello! Welcome to Wheelsway. This page walks you through medical casters options and definitions, specs, OEM, and FAQs—so you can choose the right solution fast.

Medical casters are specialised wheeled devices consisting of wheels and brackets that are mounted on medical equipment, furniture or fixtures for ease of movement in medical environments such as hospitals, clinics and laboratories. They can be attached to a variety of equipment, including medical beds, surgical tables, medical devices, and patient chairs. These casters often have features such as antimicrobial properties, central-locking mechanisms, and non-marking wheels, which ensure safe and efficient movement of equipment while maintaining a hygienic environment.

Allows heavy equipment to be moved easily, then securely locked in position.

Maintains a stable and level setup, essential for precision or sensitive operations.

Often includes anti-vibration pads to absorb shock, minimize noise, and prevent shifting during use.

Built from strong materials (e.g., die-cast aluminum, impact-resistant Nylon) for long-term serving life.

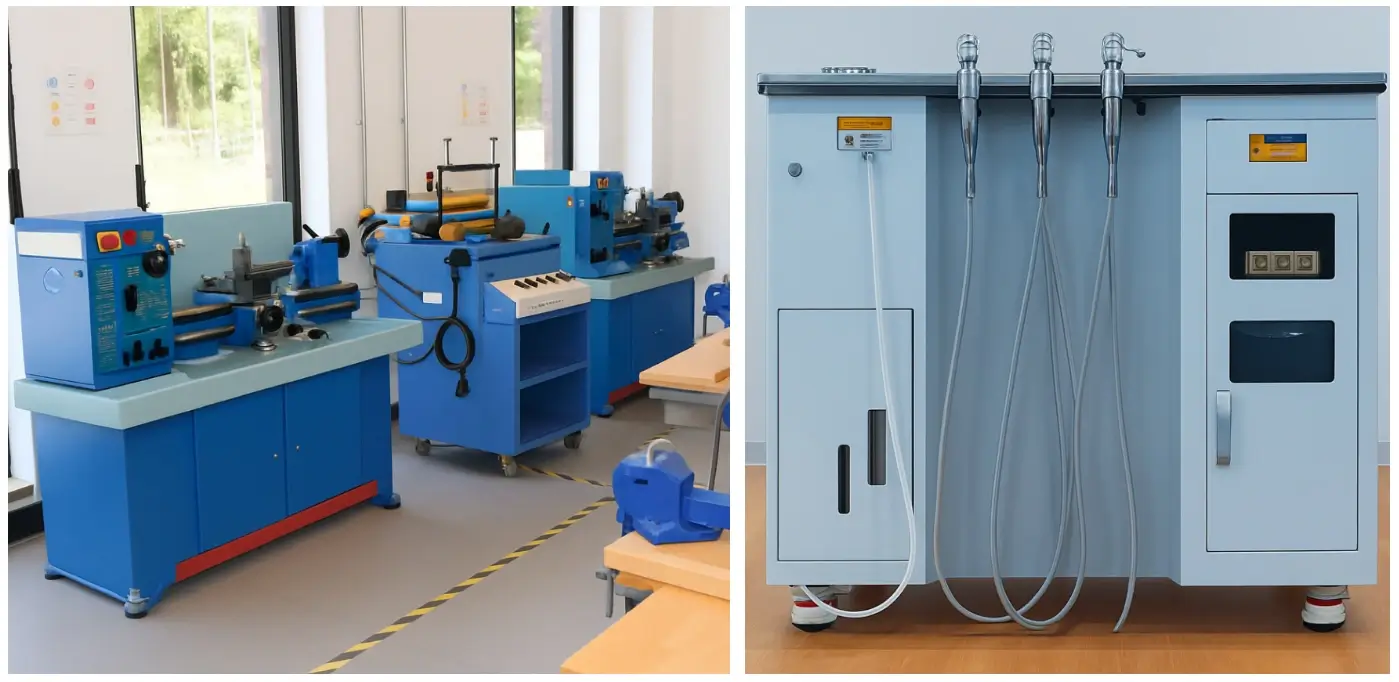

Vending machine, workshop machinery, hospital equipment, precison manufacuring, semi conductive equipment, labtory equipment, 3D printer, industrial shredder machine, etc

Our range helps you reduce overall height, protect sensitive instruments, and speed changeovers

24~72 hours salt spray test passed

500 hours salt spray test passed

1,000 hours salt spray test passed

50mm~100mm

Bearing: Double ball bearings

Bearing: Double ball bearings

Up to 600KGs

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

Use low-height leveling casters for industrial workbenches.

Caster load capacity calculation:

1. When rolling, braking, or crossing a bump, the center of gravity shifts diagonally, two opposite casters momentarily take 80–100 % of the total load. 1pc load= (bench weight+max tool weight)/2

2. Even a 1–2 mm difference in height or ground flatness can lift one caster off the floor. 1pc load= (bench weight+max tool weight)/3

For better and quicker adjusting the leveling caster, choose our LV1 or LV2 series with ratchet-level system

Detailed information → #Wheelsway leveling caster specifications

A leveling caster is a hybrid component combining a swivel wheel (caster) and an adjustable leveling pad/foot.

The leveling adjustment is achieved via mechanisms like threaded stems, manual thumb-wheels, nuts, ratchets or foot-pedals depending on design and load capacity.

In the leveling/stationary mode the pad is lowered until it contacts the floor, lifting the wheel (or unloading it) and immobilising the equipment.

These casters allow equipment to be mobile for repositioning and then secure/level when in use, eliminating separate wheels + leveling feet assemblies.

A low-profile caster swivel is a compact caster that allows 360° rotation for smooth maneuvering in tight spaces, and low profile casters with brakes is swivel low profile caster equipped with a brake to lock movement when the unit is stationary.

For more details, see #Wheelsway low profile casters

we are just one click away

*We respect your privacy and all your information are protected.