expert casters for equipment that requires minimum caster assembly height and stable set up.

Leveling casters are caster wheels with an adjustable leveling mechanism, such as a foot pad, lever, or threaded screw that stabilizes equipment on uneven floors. Roll into position, then lower the pad to lock and level for a rigid, low-vibration footing, ideal for CNC workstations, lab benches, test rigs and more.

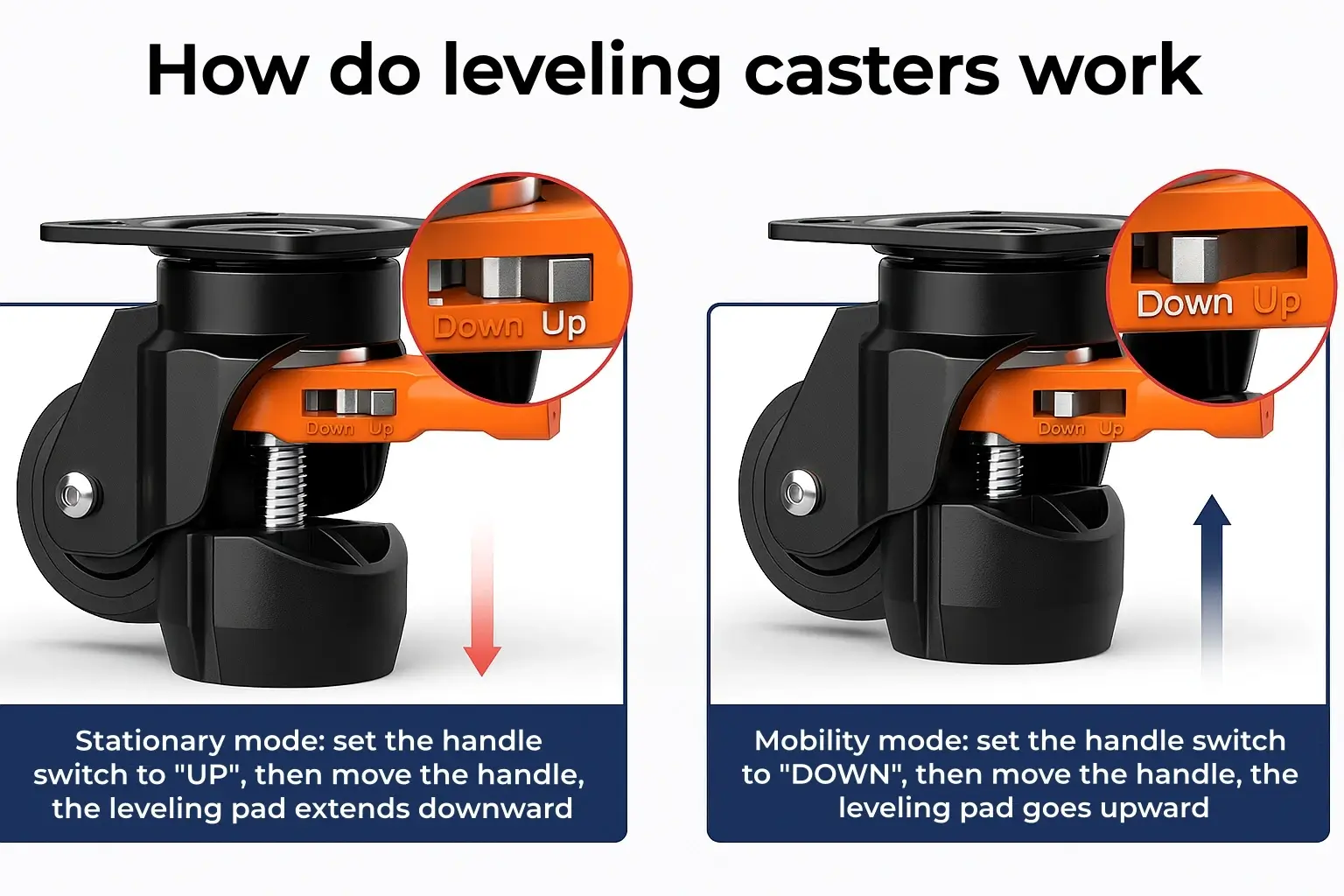

Leveling casters have two modes: Stationary and Mobility.

· When the pad is raised, the wheel supports the load and rolls freely.

· When the pad is lowered, it presses against the floor and lifts or unloads the wheel, locking the equipment in place.

The pad is adjusted by a screw or lever, providing stable, level, and vibration-reduced support.

Allows heavy equipment to be moved easily, then securely locked in position.

Maintains a stable and level setup, essential for precision or sensitive operations.

Often includes anti-vibration pads to absorb shock, minimize noise, and prevent shifting during use.

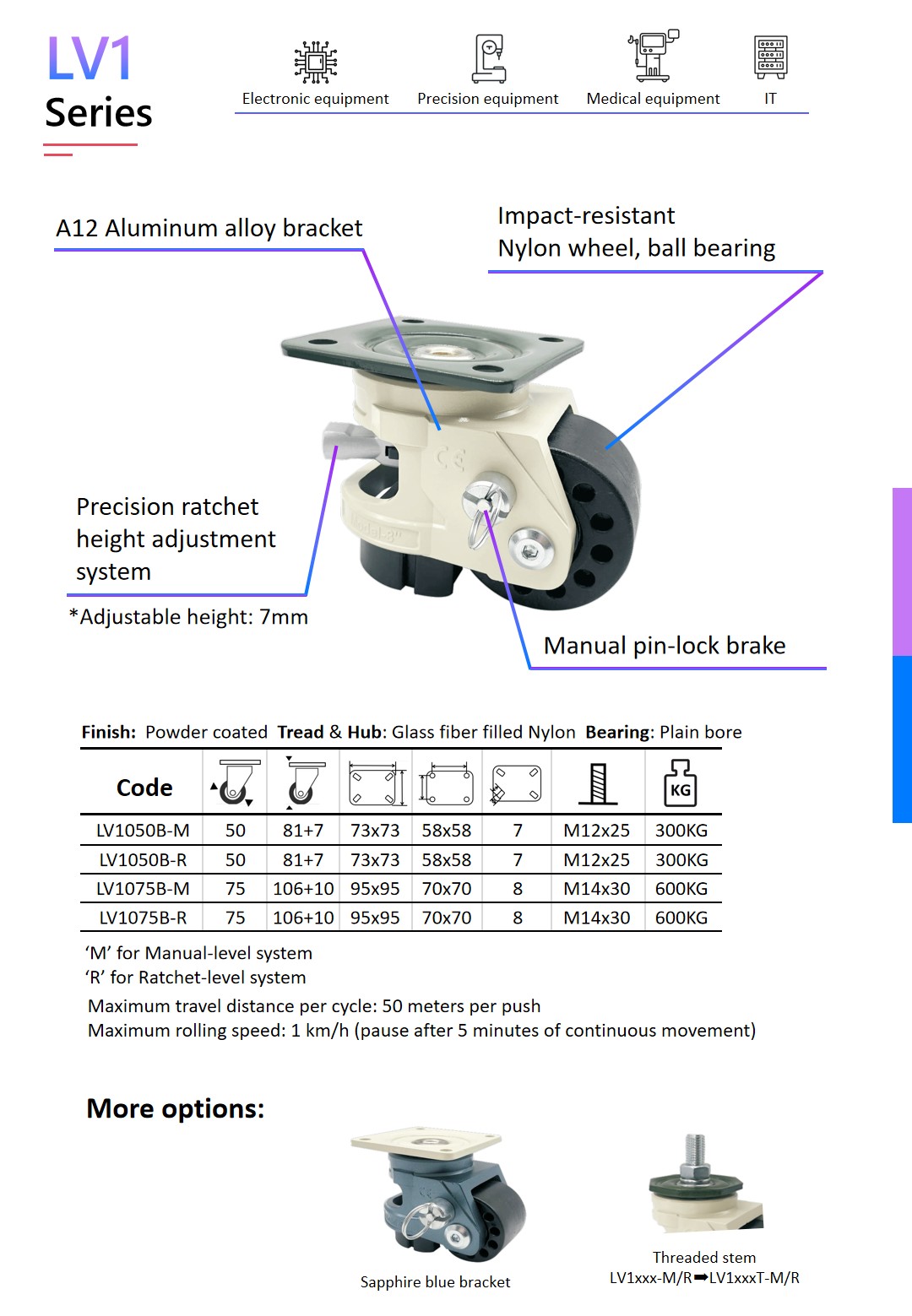

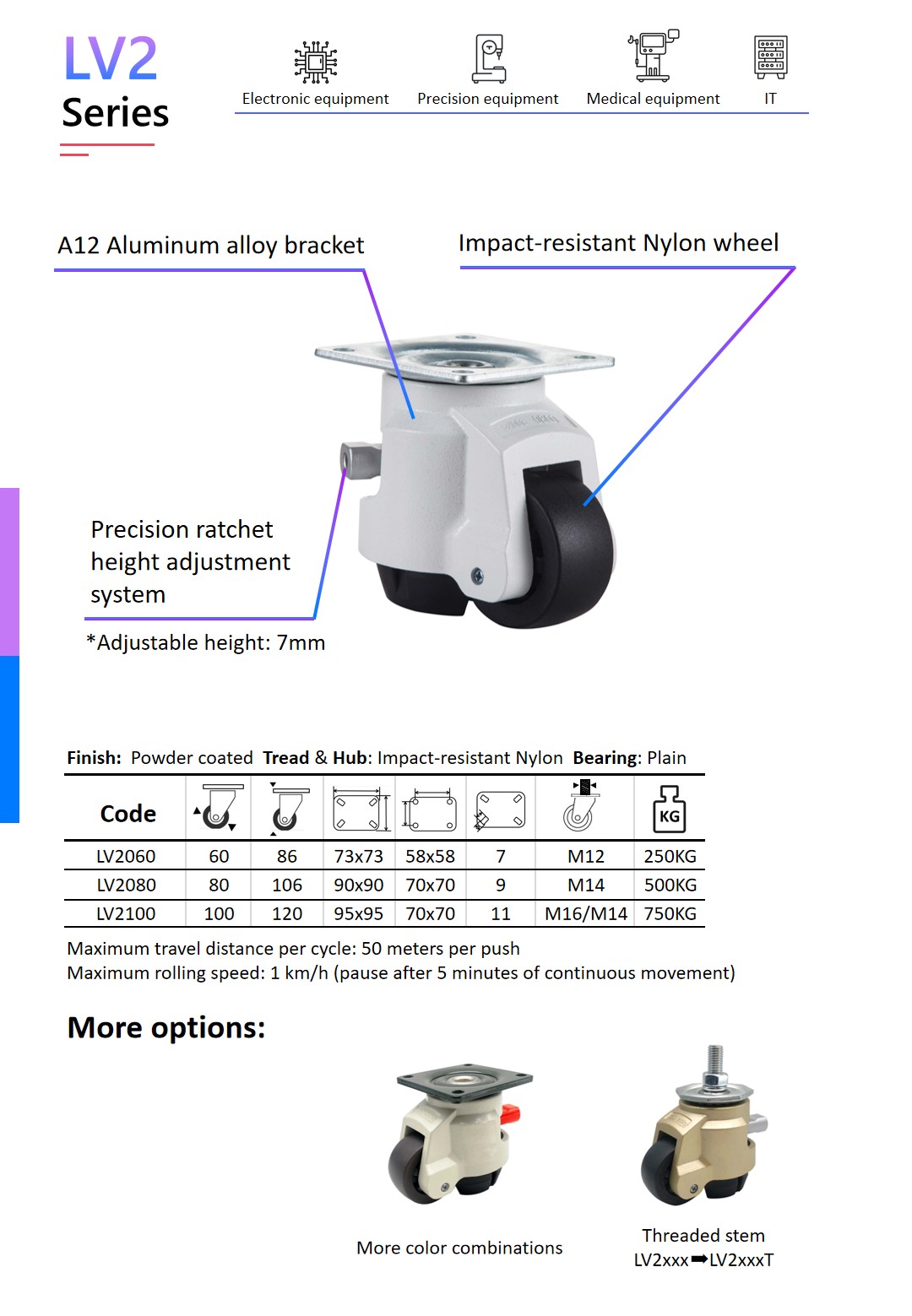

Built from strong materials (e.g., die-cast aluminum, impact-resistant Nylon) for long-term serving life.

Vending machine, workshop machinery, hospital equipment, precison manufacuring, semi conductive equipment, labtory equipment, 3D printer, industrial shredder machine, etc

Roll your equipment into place, lock it, then level for a rock-steady, low-vibration setup.

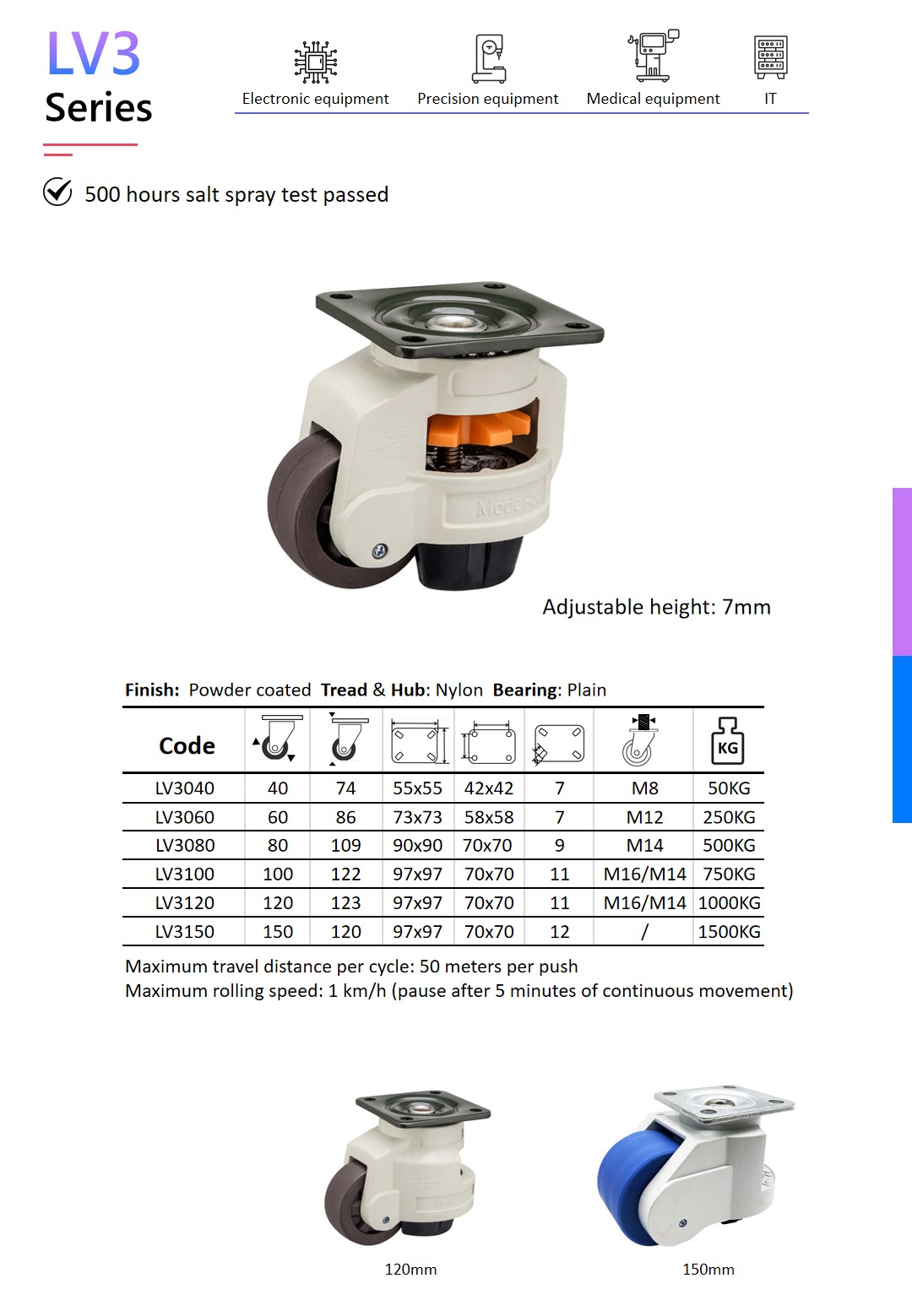

500 hours salt spray test passed

50mm~150mm

Bearing options: Plain bore / Plain bushing

Bearing options: Plain bore / Plain bushing

Up to 1,500KGs

| Criteria | Leveling casters | Low-profile casters |

|---|---|---|

| Core purpose |

Designed to create a stable, level base on uneven floors or when precise leveling is required under load. They combine mobility with a leveling mechanism to compensate for floor irregularities. |

Designed to minimize overall height while preserving mobility and load-bearing capacity. They emphasize space efficiency and clearance rather than dynamic leveling. |

| When to use |

Use when equipment must operate level in place (e.g., machinery bases, workstations, hospital beds, or heavy carts that must be leveled during operation). |

Use when clearance is limited (under cabinets, server racks, display cases, or slim furniture) and mobility is needed without compromising height constraints. |

| Mechanism and components |

Incorporate a leveling element (foot pad, screw jack, lever-operated pad, or auto-leveling actuator) that engages to raise or stabilize the wheel/contact surface. Often include a locking or braking function that works in tandem with leveling. |

Feature a reduced overall mounting height, often with a broader wheel footprint or reinforced frames to maintain stability at a lower height. They may be rigid (no swivel) or swivel with brakes, but typically do not include an active leveling mechanism. |

| Load and stability behavior |

Prioritize static and dynamic stability at a level state; performance is judged by leveling accuracy, repeatability, and how well the load remains level under movement or varying loads. |

Prioritize maximizing load capacity relative to their compact height, stability during movement, and floor interface, with emphasis on minimizing interference with surrounding spaces. |

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

Leveling casters are caster wheels with an adjustable leveling mechanism—such as a foot pad, lever, or threaded screw—that stabilizes equipment on uneven floors.

Once the equipment is in position, you use a knob or tool to lower a pad beneath the caster. That pad touches the floor and lifts the wheel slightly, so the load rests on the pad — not the wheel. This keeps the equipment from shifting or vibrating, even on uneven surfaces. It’s simple and reliable.

You’ll find them in factories, cleanrooms, labs, and electronics assembly lines. Common uses include mobile workbenches, inspection tables, medical equipment, and industrial machines.

It depends on the model. Some leveling casters handle around 100 kg, while heavy-duty options go well over 2000 kg per caster. For industrial setups, make sure to check the rated load and apply a safety factor — for example, divide the total weight by three instead of four if using four casters.

Leveling feet are static. You bolt them in and adjust the height manually, but they don’t move. Leveling casters, on the other hand, let you roll the equipment where you need it — then level and secure it in place. They’re ideal for setups that get moved around but still need vibration control and leveling.

Start with the load capacity and mounting style. Do you need plate-mount or stem-mount (like M12 or M16 threads)? Consider the floor surface — softer wheels for delicate floors, harder ones for durability. Stainless steel for corrosive areas. If your equipment is sensitive, look for anti-vibration pads or low-profile designs.

Standard casters stop the wheel from turning, but they don’t prevent vibration or slight movement, especially under load. Leveling casters lift the wheel entirely off the ground — the load sits on a solid pad. That’s much more stable. If you’re running a precision machine or test station, it makes a big difference.

You can source leveling casters through industrial suppliers or regional distributors. If you’re looking for reliable advice and fast global delivery, WheelsWay Caster is here to help. We ship worldwide and provide detailed spec sheets to match your needs. Need help selecting the right caster? Contact us — our team will guide you.

Yes, if your equipment gets moved often or needs precise leveling. They cost more than standard casters, but you’ll save time and avoid the hassle of jacks or separate feet. Plus, fewer injuries, less downtime, and more floor layout flexibility. For many factories, labs, and machine builders — it’s a solid investment.

we are just one click away

*We respect your privacy and all your information are protected.