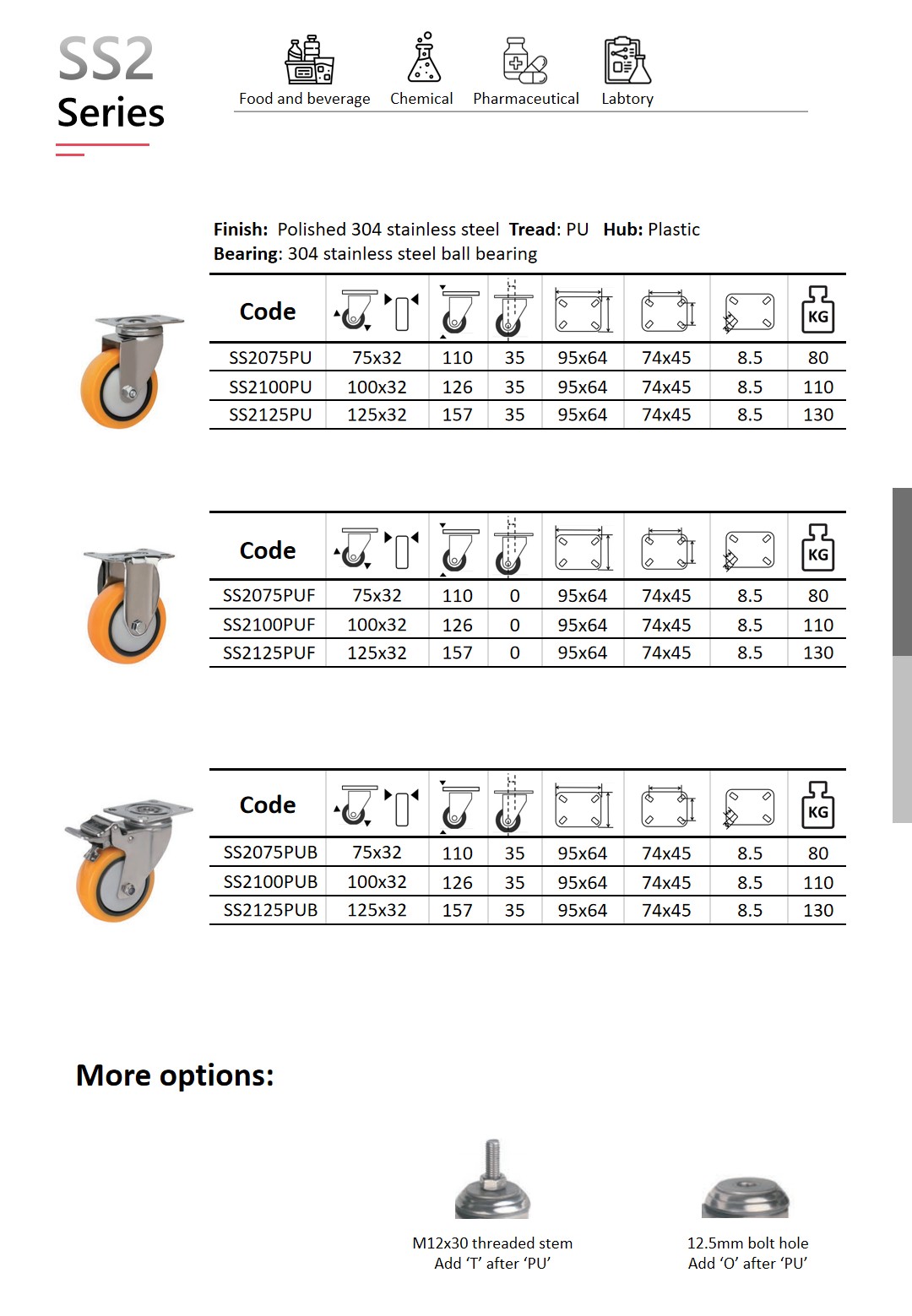

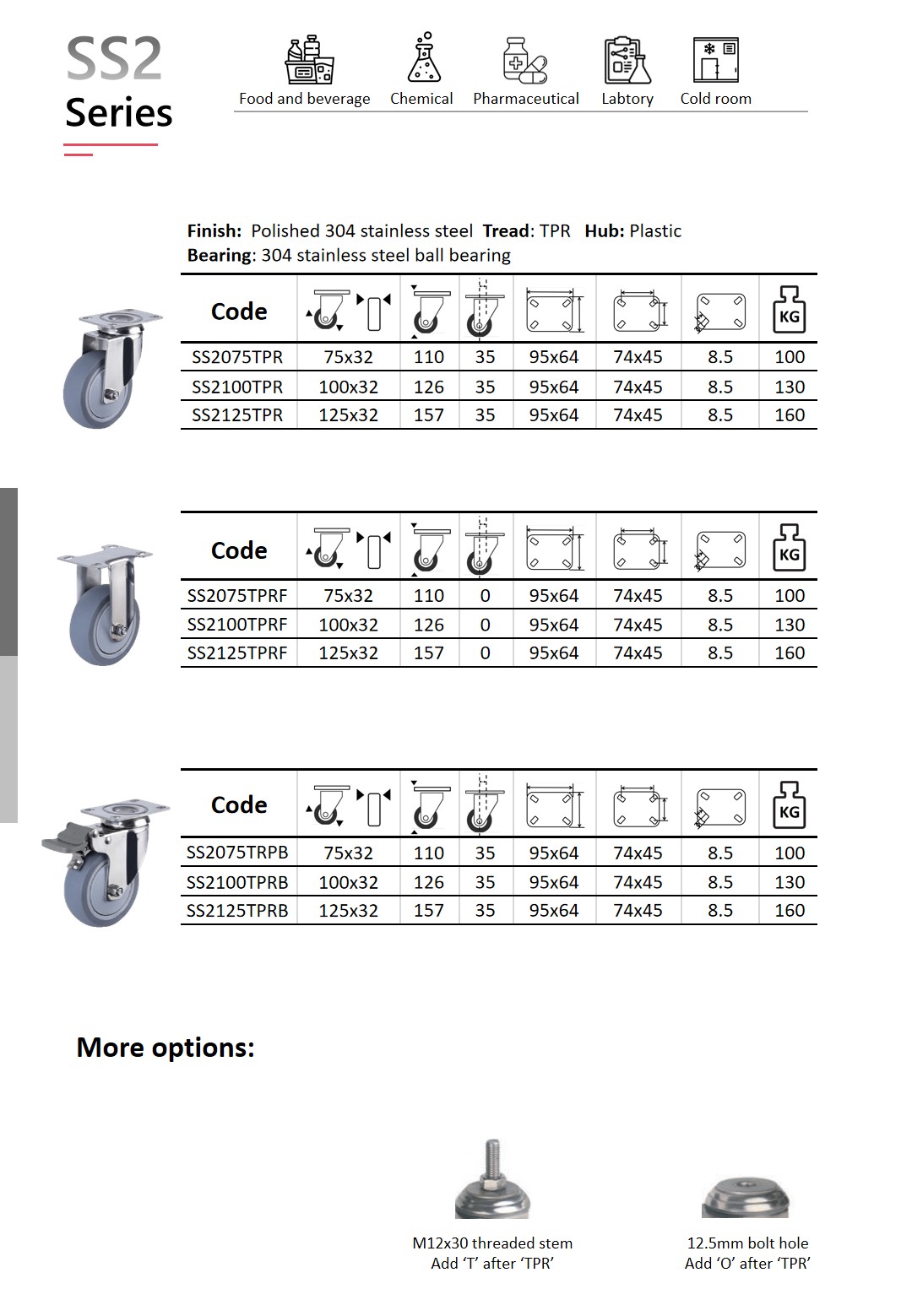

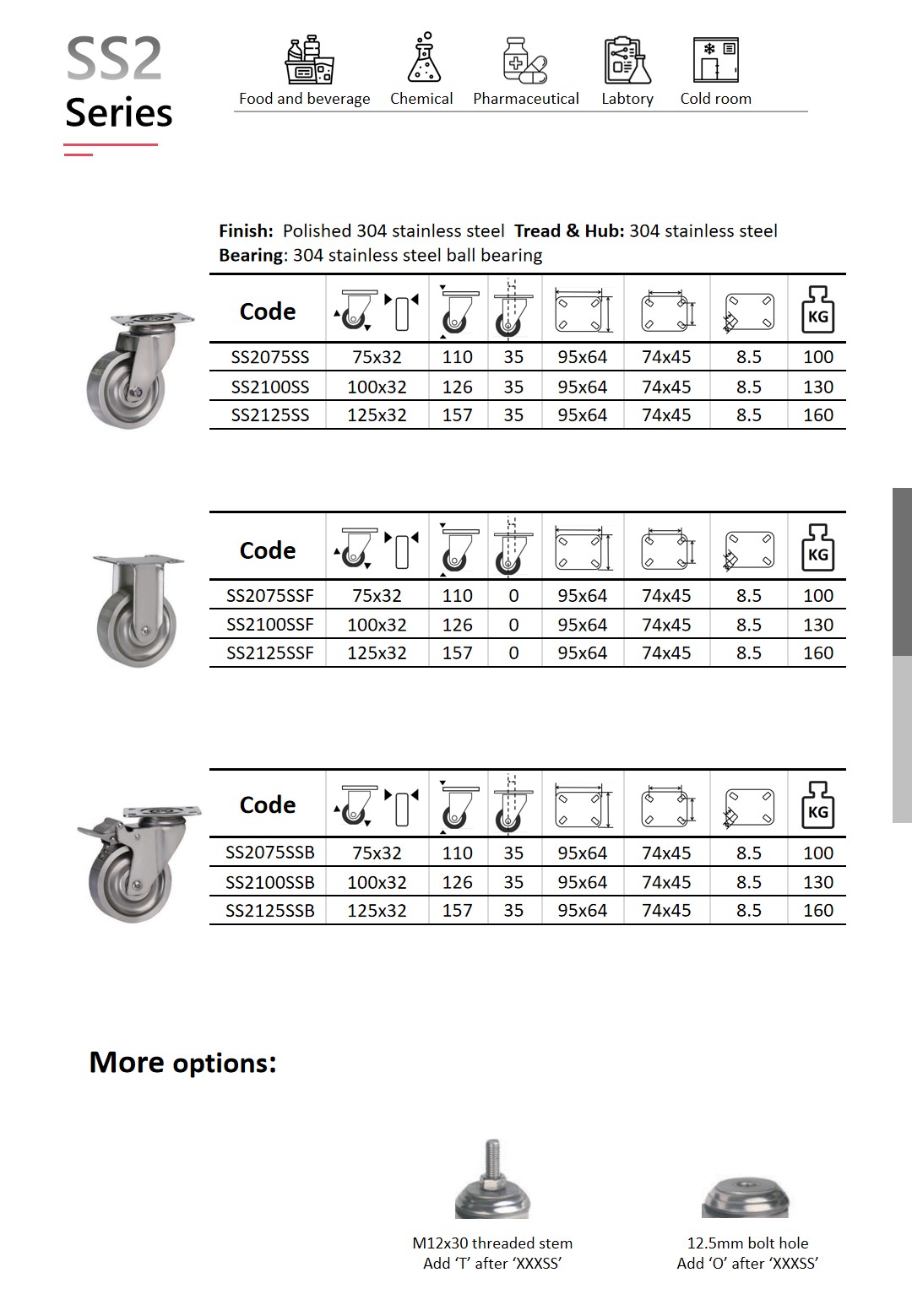

for food processing, food service, medical, pharmaceutical, laboratory and Industrial & material‑handling.

Hello! Welcome to Wheelsway. This page introduces our 304 stainless steel casters, covering definitions, common applications, and technical specifications. If you’re looking for more details or have a specific project in mind, you’re welcome to reach out and start a conversation. Let’s talk!

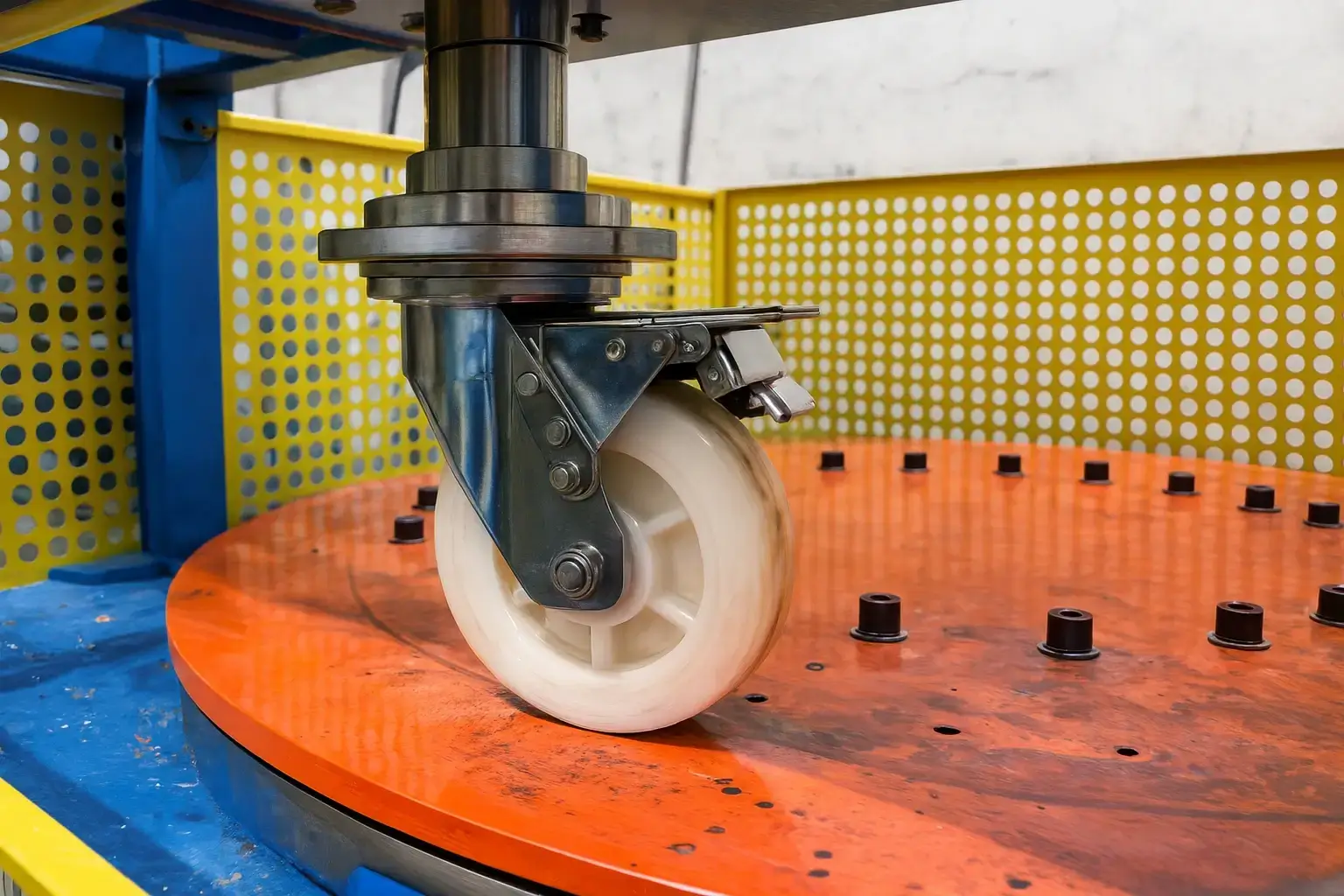

A stainless steel caster is a wheel assembly whose metal parts and components are made from a chromium‑bearing stainless steel alloy. The chromium in the alloy reacts with oxygen to form a passive layer that prevents iron from rusting and corroding. We typically use 304 stainless steel. 304 contains 16–24 % chromium and offers excellent corrosion resistance. By combining high strength with easy cleaning and long service life , they provide reliable mobility in harsh, wet or sanitary environments where ordinary steel casters would fail.

durable corrosion resistance in humid, chemically cleaned, and chloride‑containing environments typical of food plants, pharma wash‑down, and marine service.

Smooth, non‑porous stainless steel resists microbial growth and prevents flaking or rust that could contaminate clean areas or compromise validation.

In many product lines, stainless and zinc‑plated versions share the same nominal load ratings but differ in corrosion performance and service life.

Industrial grade stainless steel casters for lab utility cart, fluid management machine, medical cart, medical trolley, pharmaceutical waste transport cart, etc

1,000 hours salt spray test passed

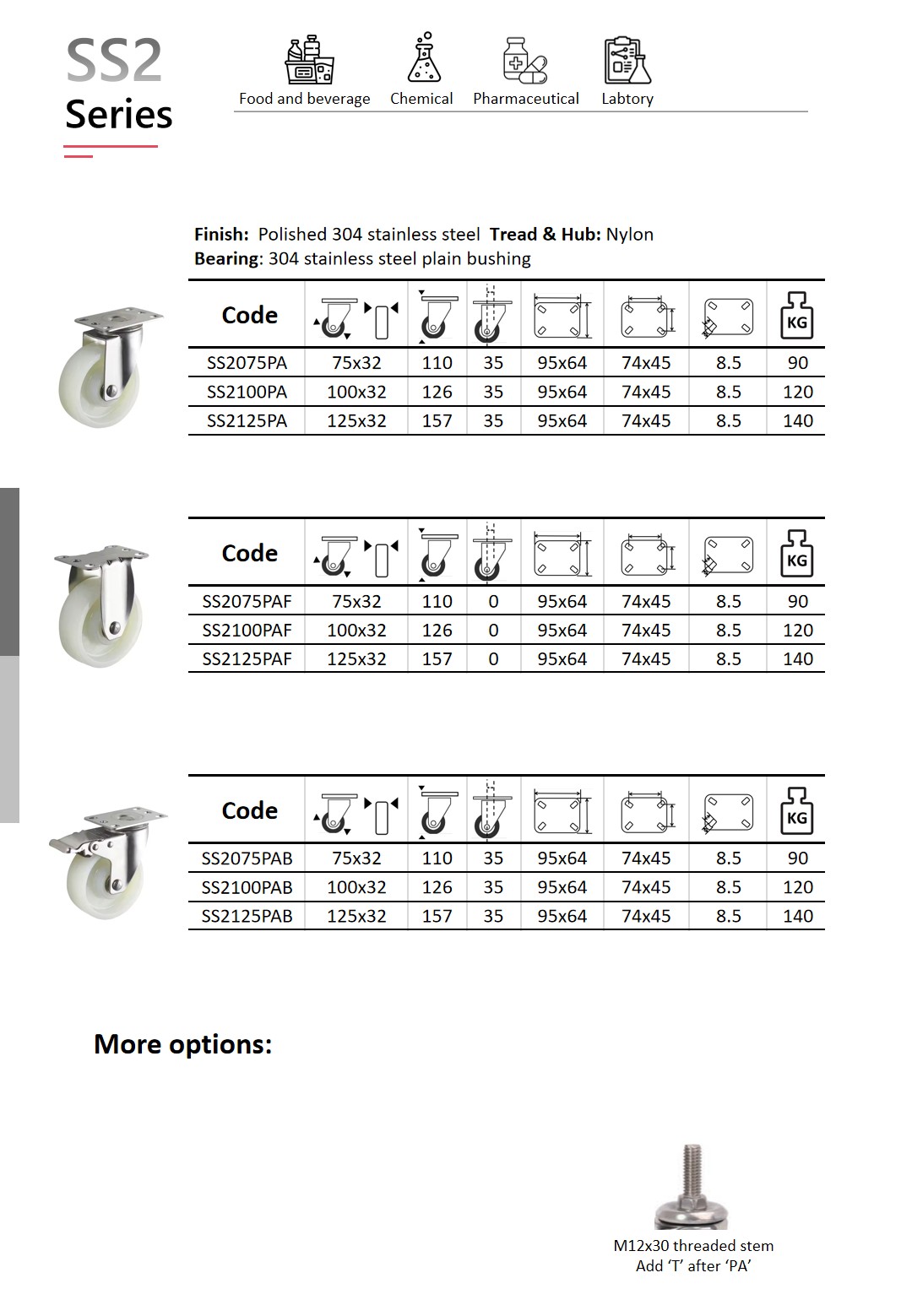

75mm, 100mm, 125mm

Bearing: Single ball bearing; With wheel cap; PU Color customizable

Bearing: Single ball bearing; With wheel cap; Black color Nylon wheel available

Bearing: Roller bearing

Bearing: stainless steel ball bearings

30KG~50KG

Catalog page too small? Click to zoom in or out, then drag to navigate the enlarged view.

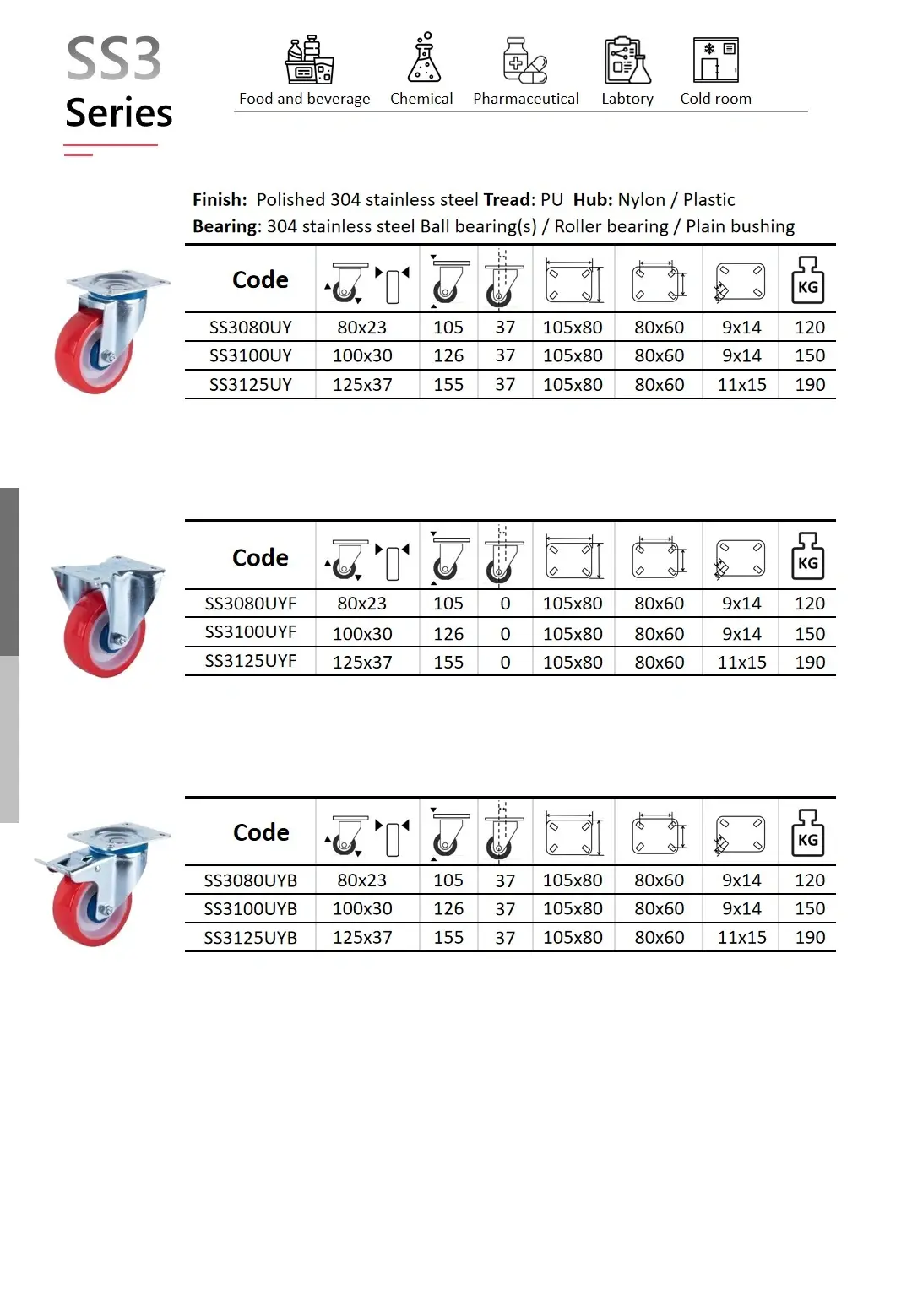

1,000 hours salt spray test passed

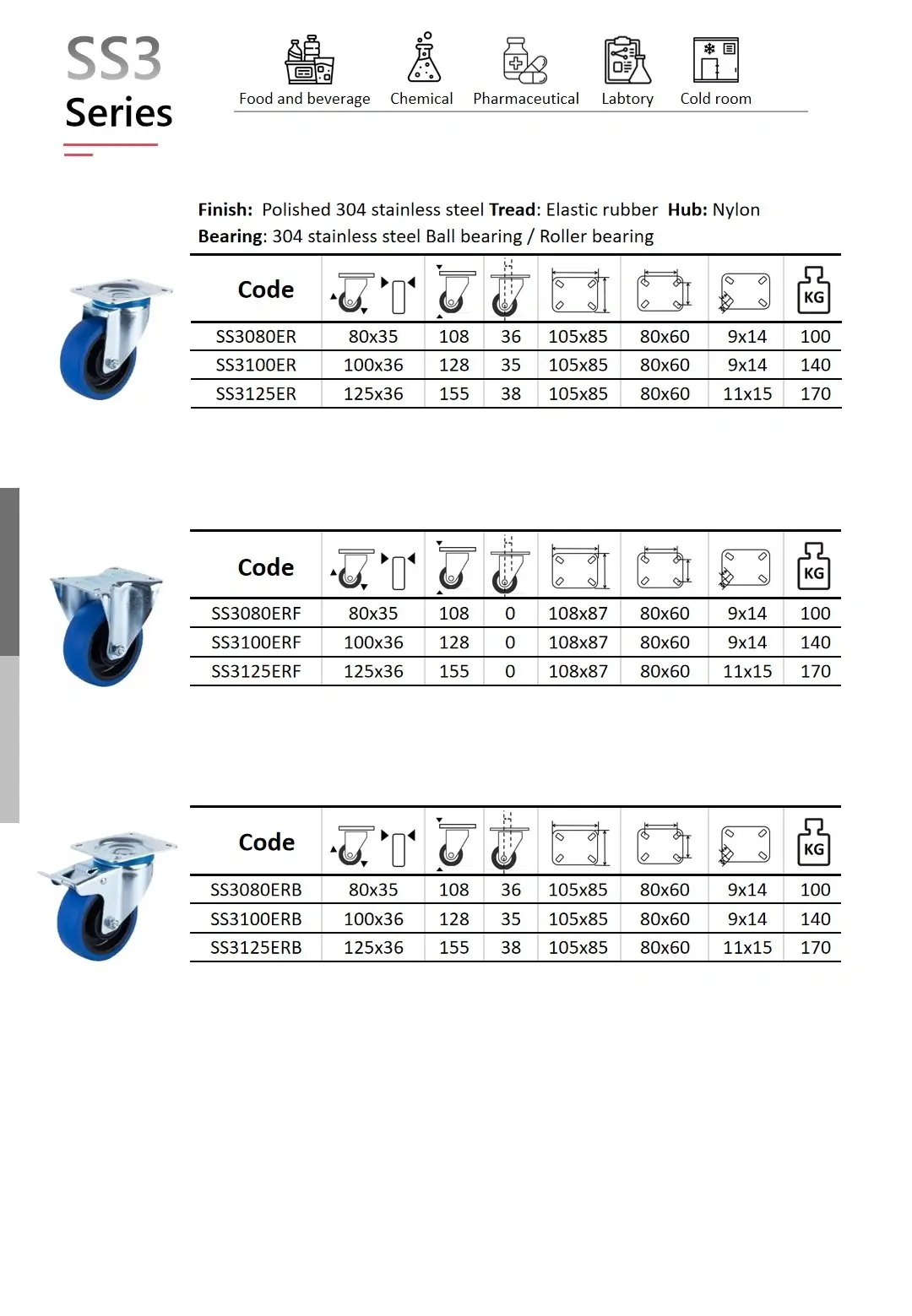

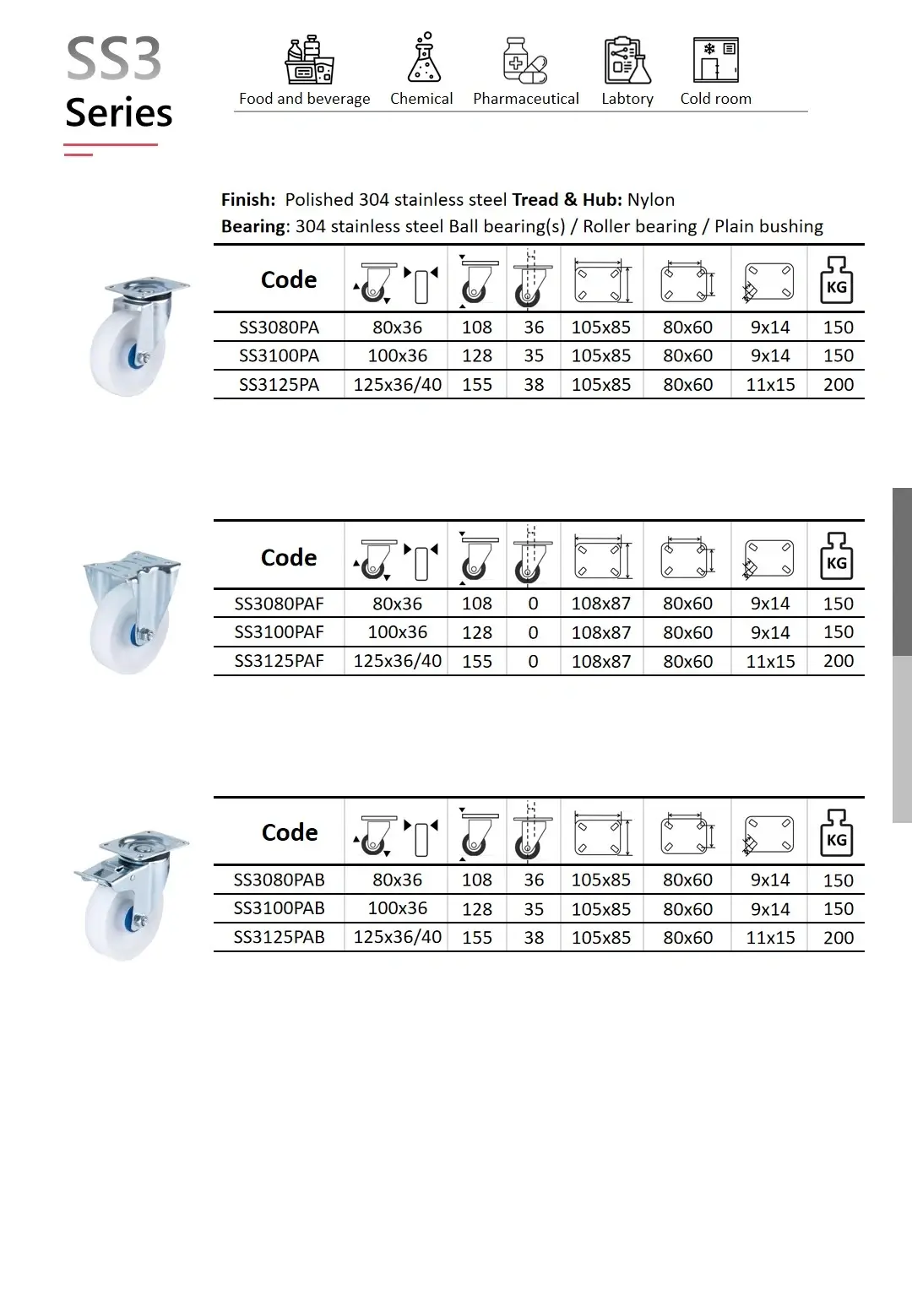

80mm, 100mm, 125mm

Bearing options: SUS304 ball bearings, SUS304 roller bearing; SUS304 plain bushing

Bearing options: SUS304 ball bearings, SUS304 roller bearing; SUS304 plain bushing

Bearing options: SUS304 ball bearings, SUS304 roller bearing

30KG~50KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

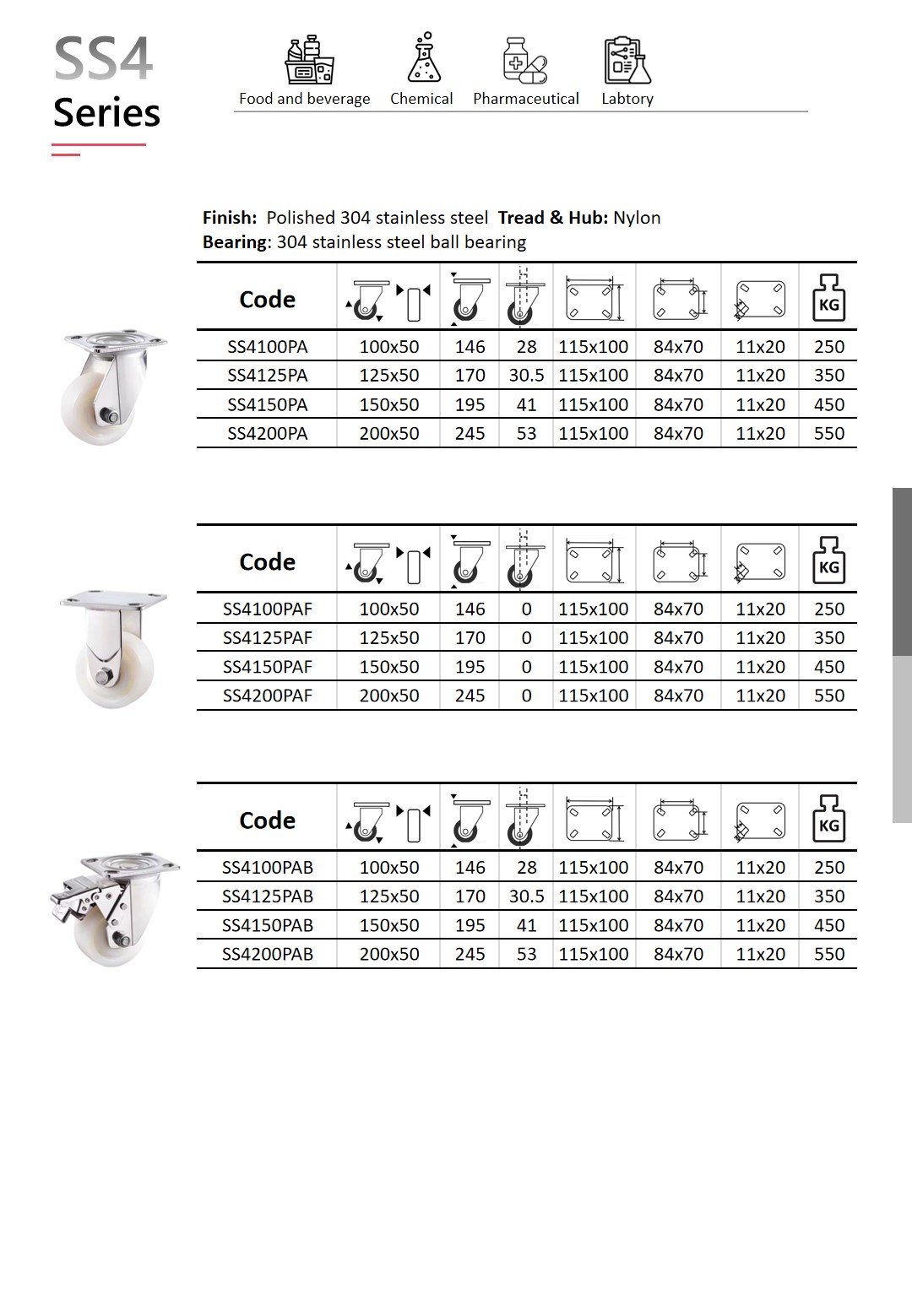

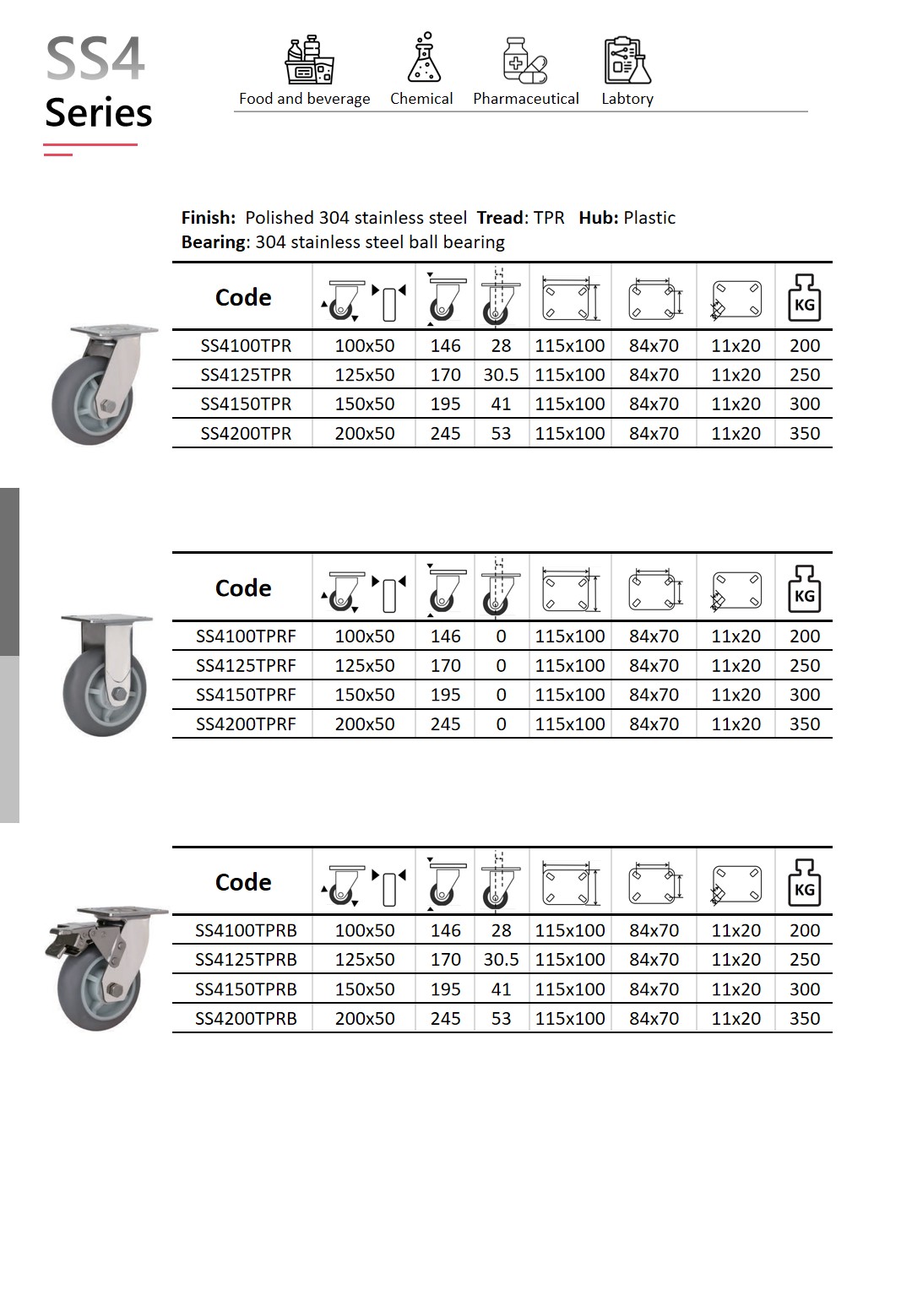

1,000 hours salt spray test passed

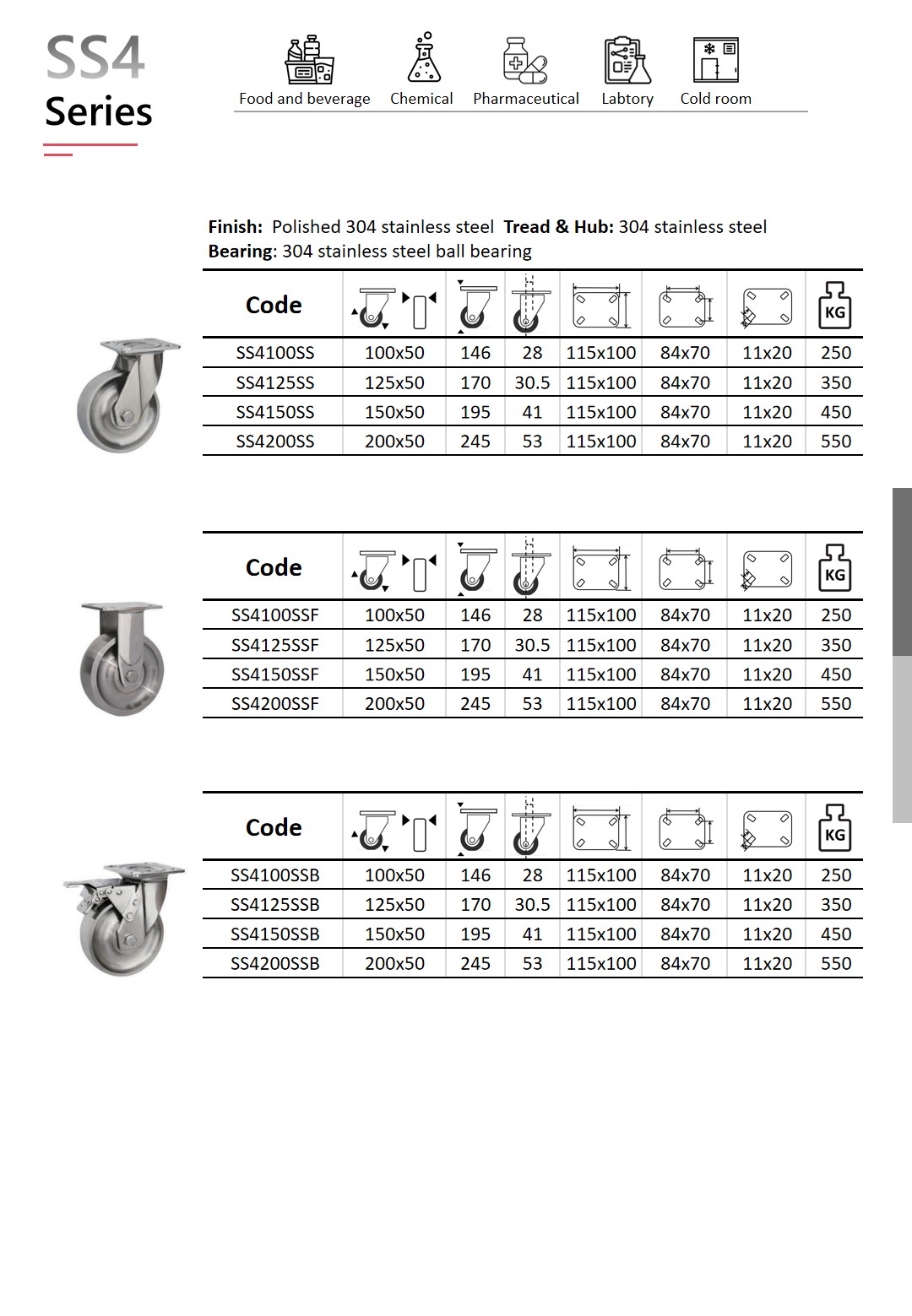

100mm, 12500mm, 150mm, 200mm

Bearing options: SUS304 ball bearings, SUS304 roller bearing

Bearing options: SUS304 ball bearings, SUS304 roller bearing

Bearing options: SUS304 ball bearings, SUS304 roller bearing; SUS304 plain bushing

Bearing: stainless steel ball bearings

200KG~550KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

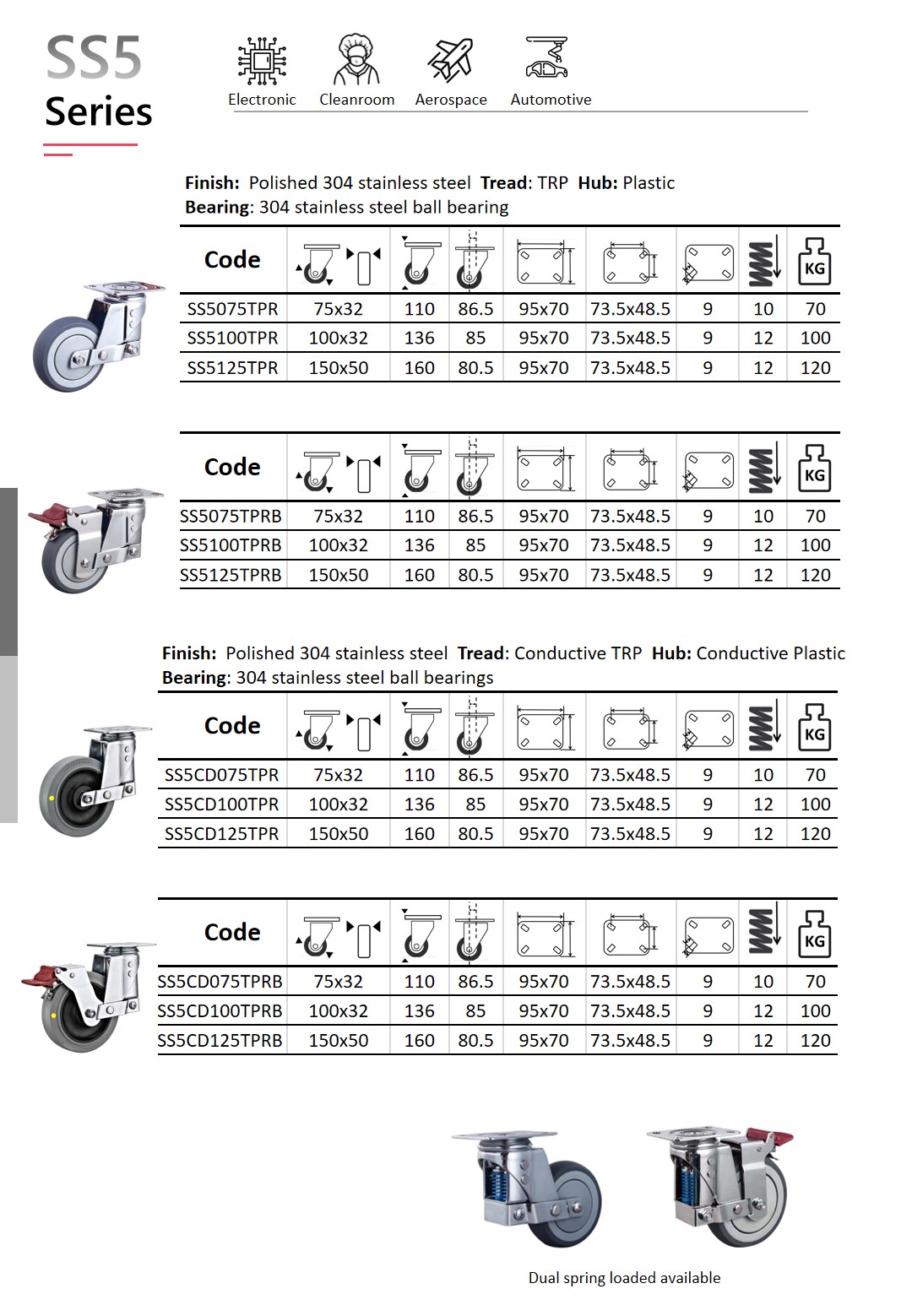

Shock absorbent casters for car part handle trolly, automotive assembly line trolley, etc

1,000 hours salt spray test passed

75mm, 100mm, 125mm

Bearing: Stainless steel ball bearings; Wheel cap available

Bearing: Single ball bearing; With wheel cap

70KG~120KG

Product catalog too small? Click to zoom in or out, then drag to navigate the enlarged view.

Stainless steel resists corrosion by forming a thin, invisible chromium-oxide passive layer that protects it from oxygen and moisture. However, this protection is not permanent. In aggressive environments—such as exposure to chlorides, high humidity, acids, or stagnant water—the passive layer can break down faster than it can repair itself. Surface contamination, inadequate cleaning, or moisture trapped in crevices can further accelerate corrosion, leading to pitting, crevice corrosion, or tea staining, especially in grades like 304.

Austenitic stainless steels (such as 304, 316), which are normally considered non‑magnetic in the annealed state, can become slightly magnetic in areas that have been cold worked, including sheared edges, punched holes, bends, and deep‑drawn regions. This magnetism arises because cold work can transform some of the non‑magnetic austenite into martensite , which is ferromagnetic.

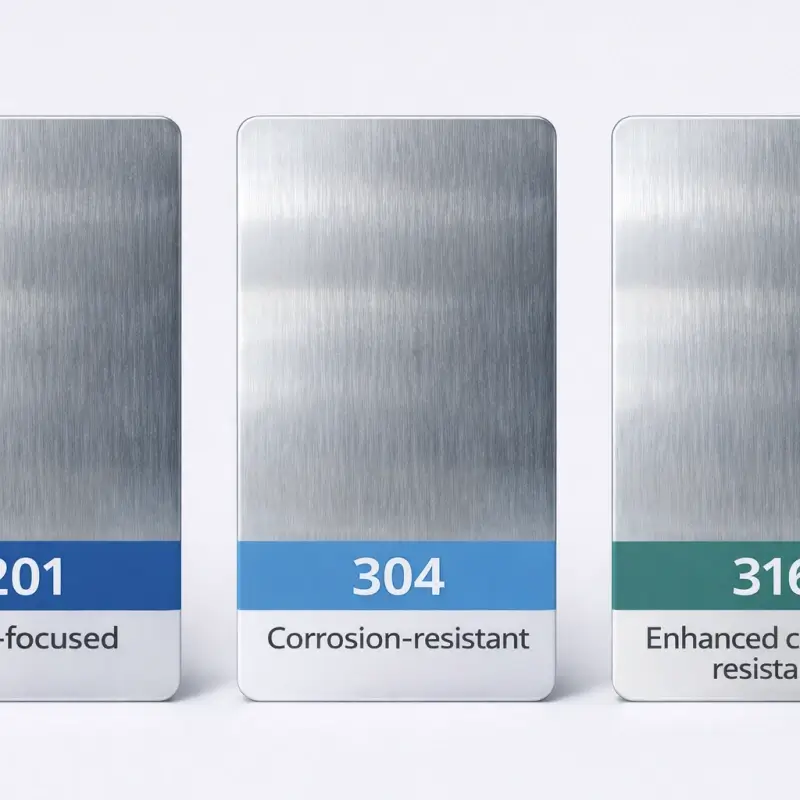

ASM and Nickel Institute–type data confirm that 304 is a Cr–Ni austenitic, while 201 is Cr–Mn–Ni with reduced nickel and increased manganese/nitrogen to maintain austenite.

Nominal ranges (weight‑%) for flat products:

| Element | 304 | 201 | 316 |

|---|---|---|---|

| Carbon |

≤ 0.08 |

≤ 0.15 |

≤ 0.08 |

| Chromium |

18.0–20.0 |

16.0–18.0 |

16.0–18.0 |

| Nickel |

8.0–10.5 |

3.5–5.5 |

10-14 |

| Manganese |

≤ 2.0 |

5.5–7.5 |

≤ 2.0 |

| Nitrogen |

≤ 0.10 |

0.05–0.25 |

≤ 0.10 |

| Molybdenum |

----- |

----- |

2.0-3.0 |

| Silicon |

≤ 0.75 |

≤ 1 |

≤ 0.75 |

Representative minimum properties for annealed flat products:

| Property (annealed) | 304 | 201 | 316 |

|---|---|---|---|

| Tensile Rm |

500–700 MPa |

750–950 MPa |

515-760 |

| 0.2% proof (Rp0.2) |

≈ 210–230 Mpa |

≈ 230 MPa min; temper‑rolled up to > 450 MPa |

≈220-240 Mpa |

| Elongation A |

≥ 40% |

≥ 35–40% |

≥ 40% |

| Hardness HB (max) |

≈ 200 HB |

≈ 260 HB |

≈ 220 HB |

EN 12527 is the foundational European standard that defines how to test the performance of caster wheels and castors. It specifies in detail the test methods and apparatus used to evaluate factors like strength, durability, and safety. (standards.iteh.ai). This standard itself does not set the pass/fail values for every caster type; instead, it provides general procedures. Specific acceptance criteria for different caster categories (furniture, medical, industrial, etc.) are given in the respective specialized standards

EN 12530 specifies the technical requirements, dimensions, and testing criteria for castors and wheels used in manually propelled institutional applications. This standard covers medium-duty equipment castors found in public and institutional facilities such as shops, restaurants, hotels, schools, and hospitals. Castors under EN 12530 may include features like wheel brakes or swivel locks, as these are common in carts and equipment used in such environments. The standard ensures that these casters meet appropriate safety and performance levels for frequent manual handling in public spaces

EN 12532 addresses transport castors and wheels intended for industrial applications where equipment is moved at speeds up to 1.1 m/s (4 km/h). This is roughly a fast walking speed, indicating the standard is for carts or trolleys that might be pushed or towed slowly in warehouses or factories. The standard lays out technical requirements, dimensions, and testing for casters used on non-powered or hand-towed industrial transport equipment. EN 12532 explicitly excludes certain categories: it does not apply to furniture or office chair casters, institutional or hospital bed casters, or any powered/driven equipment casters. Those excluded categories are covered by other standards (e.g., furniture by EN 12528/12529, hospital by EN 12531, and higher-speed driven equipment by EN 12533). Essentially, EN 12532 is focused on wheels and castors for manually propelled or tugged industrial carts and platform trucks operating at low speeds.

Designing and manufacturing custom casters for an OEM project involves several stages, we follow a detailed step-by-step process to ensure that your project runs smoothly and without any problems

Define requirements: Understand the customer’s specific needs and requirements. Consider special attachments, test standards, and industry standards. Give suggestions to improve the caster performance if the customer wants to eliminate the failure issues from their existing casters.

Material selection: Select appropriate wheel materials for the casters based on factors like load capacity, environmental conditions, and durability requirements.

Technical Drawings: Make detailed 2D/3D technical drawings of the caster based on the customer’s requirements or samples.

Prototyping: Develop prototypes to test the functionality and performance of the casters. It can be a 3D printing model or a small batch for initial testing.

Tooling and Equipment Setup: On the basis of the finalized design, set up and adjust the necessary tooling and equipment for mass production.

Production of Components: Manufacture individual caster components such as wheels and frames, according to technical specifications in confirmed drawings.

Surface Treatment: Apply surface treatments to enhance the aesthetics, corrosion resistance, hardness, or other functional aspects of the casters.

Assembly: Assemble the casters, making sure that each unit meets the design specifications and quality standards.

Load Testing: Test the casters according to the dynamic load test standard, such as EN12532, or conform to the test requirements of the customer. To ensure that the casters can handle the specified weight capacities without failure.

Durability Testing: Test the casters for durability under various conditions, such as different floor surfaces and temperature extremes, according to the customer’s demand.

Quality Control Checks: Implement ISO9001 quality control measures throughout the manufacturing process. Identify and correct any defects.

Packaging: Develop packaging solutions that protect the casters during transportation and storage.

Shipping Logistics: Plan and coordinate the logistics for shipping the casters to the client, and confirm the paperwork details with the customer, such as invoice and packing list, bill of lading, Certificate of Original, Form E, etc.

Customer Support: Provide ongoing support to address any queries, concerns, or further needs that the client may have after receiving the casters.

A stainless‑steel caster is a wheel assembly made with a chromium‑rich metal alloy that resists rust and corrosion. By preventing iron from oxidising, stainless steel allows the caster to withstand moisture and chemicals.

Zinc‑plated casters are common and inexpensive but the plating corrodes over time; stainless‑steel casters remain rust‑free because the alloy itself is corrosion‑resistant.

Kingpinless designs are preferred for harsh conditions. Traditional swivel casters use a kingpin (rivet or bolt) to join the mounting plate and fork, but this creates an open path where water and chemicals can enter and wash away lubrication, causing rust. At Wheelsway, we provide kingpinless version that fundamentally solve this problem.

The most common grades are 304 and 316. Grade 304 contains 16–24 % chromium and up to 35 % nickel, offering excellent corrosion resistance and value. Grade 316 adds molybdenum for even greater resistance to chloride or harsh chemicals but costs more. Use 316 for salt‑water or harsh cleaning agents. Our standard caster bracket is 304.

They are ideal in environments exposed to water, chemicals and corrosive agents. Typical applications include food service & hospitality (regular wash‑downs), marine settings (salt water), medical and pharmaceutical facilities (sterile conditions), food processing lines and manufacturing areas where chemicals are present

Some models are fully stainless (even for the wheel), while others are using stainless steel for metal parts including bearings except the wheel.

Wheel material affects performance: Nylon wheels are popular because they are impervious to water and most chemicals. Other options include polyurethane or rubber for quieter operation but less chemical resistance.

Yes. Nylon wheels tend to be noisier and offer poorer ergonomics; they are harder to push and pull, especially on rough surfaces.

The only difference is movement: swivel casters rotate 360° for turning, while rigid casters roll straight. On a typical cart, rigid casters are placed at the front and swivel casters at the back for control

we are just one click away

*We respect your privacy and all your information are protected.