Caster Wheel Manufacturer for Industrial Applications

Custom and bulk caster wheels supplied through a dedicated manufacturing network in China.

• OEM / ODM & private label supported;

• Custom / standard specifications & bulk production;

• Serving equipment manufacturers, distributors and project buyers;

• Not for retail

Caster Wheels Designed for Real industrial Equipment

We provide solutions that work reliably in your specific equipment, environments, and load conditions.

Medium-duty to extra heavy-duty industrial casters

Designed to bear heavy loads and reduce equipment downtime, these casters are the perfect choice for industrial and material handling equipment such like portable conveyor, pick up trolleys, flatbed carts, wire containers, aircraft engine stands, etc.

Stainless Steel Casters

With 304 / 316 stainless steel made bracket, even the wheel, these casters are for medical, food processing, and pharmaceutical equipment that require corrosion resistance, durability, hygiene and cleanability, such like cleanroom cart, lab utility cart, bakery rack, medical cart, etc.

Scaffolding Casters

With 1,200KG safe working load and compling with EN1004:2020 standard, these casters are specially for mobile scaffold towers and aluminum scaffolding.

Medical casters

Comply with EN12530 and RoHS standards, these medical casters enable smooth, controlled movement of hospital beds, carts, and medical equipment, maintaining stability, hygiene, and reliable performance in clinical environments.

Eliminate your supply chain headaches

Full customization

We adapt caster design, materials, load ratings, and mounting options to fit your equipment and end-user requirements — not the other way around.

Consistant quality

Stable specifications, controlled material sourcing, and documented change management ensure every batch performs the same

12 years experience

Over a decade of caster wheel business experience means fewer mistakes, faster decisions, and practical solutions based on real production cases.

Accountable for complaints

When issues happen, you deal with one responsible partner who investigates, responds, and resolves, instead of being passed between factories and sales reps.

Manufacturing Network, One Responsible Partner

Instead of operating a single factory, we work through a dedicated network of specialized caster manufacturers mainly in one city in China.

Each partner factory is selected based on product focus, process capability, and quality control — allowing us to match the right manufacturing setup to each application.

For our customers, this means you communicate with one partner, while production is executed by the most suitable factory behind the scenes.

We take full responsibility for:

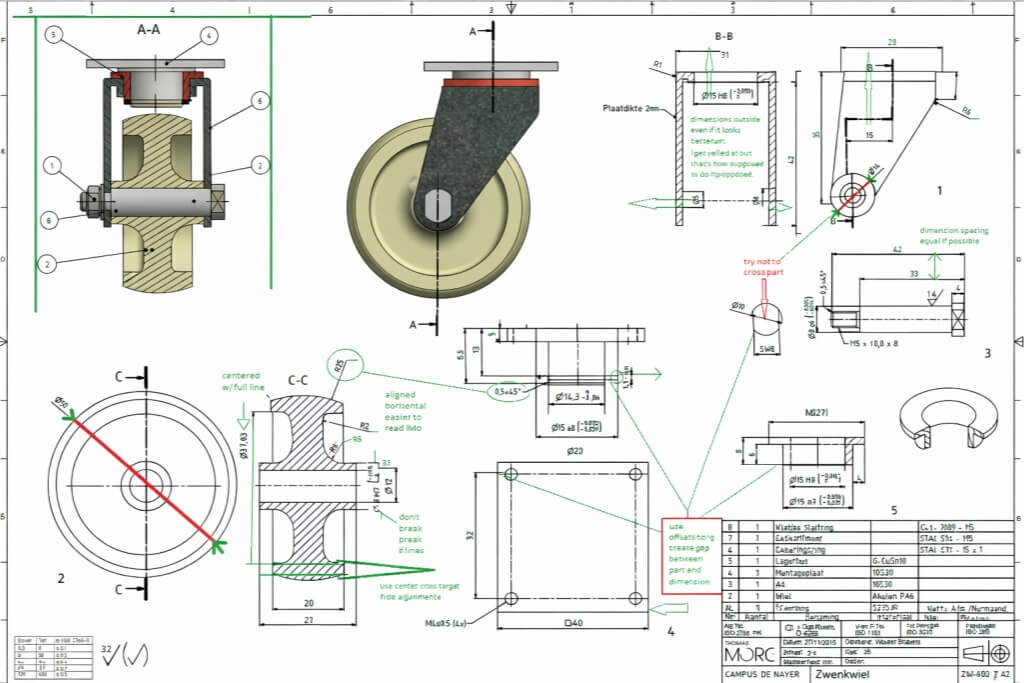

- Specification alignment and drawing review

- Factory selection and production coordination

- Quality control before shipment

- Export documentation and delivery execution

Manufacturing results are accountable to us — not passed between multiple parties.

Ready to roll your business forward?

Whether you need a quick restock of viral styles or a fully custom private label launch, we ensure consistent quality and fast sample turnaround.

B2B

Bulk purchase only

QC

Strictly controled

30~35,000KG

Load capacity covered

1~3 days

Sample Speed

Through production to final inspection & test

This structured production and testing approach ensures you receive the same performance, batch after batch — without unexpected surprises.

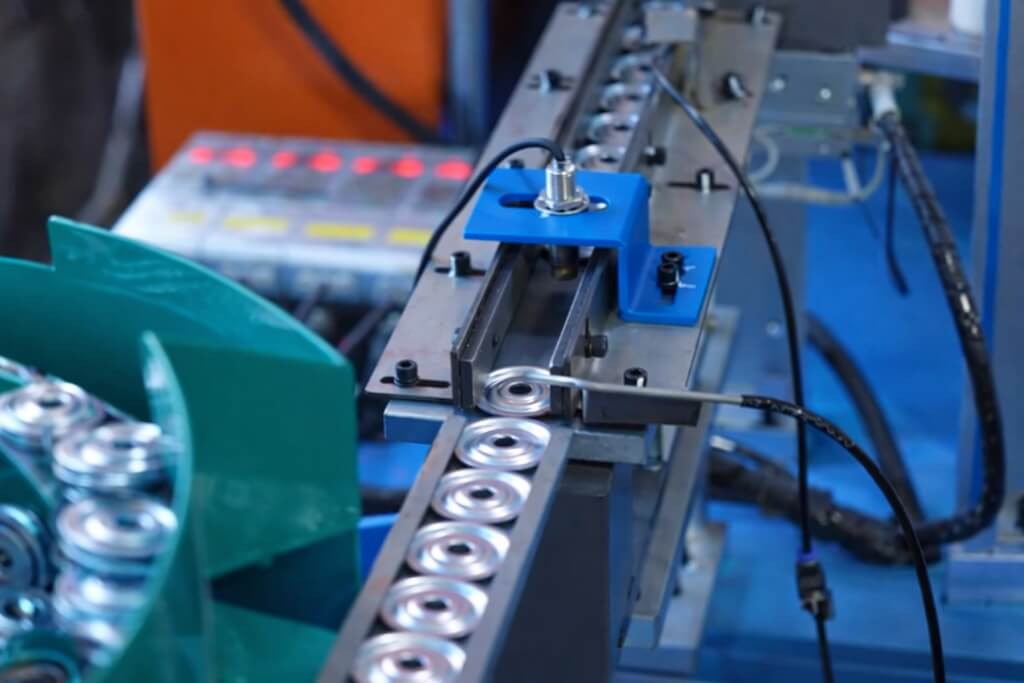

Wheel injection

Precise injection molding guarantees uniform material density, stable hardness, and consistent wheel dimensions across every production batch.

Inspection through the whole production

From raw material verification to final assembly, each stage includes dimensional checks, surface inspection, and functional validation to ensure every unit meets specification.

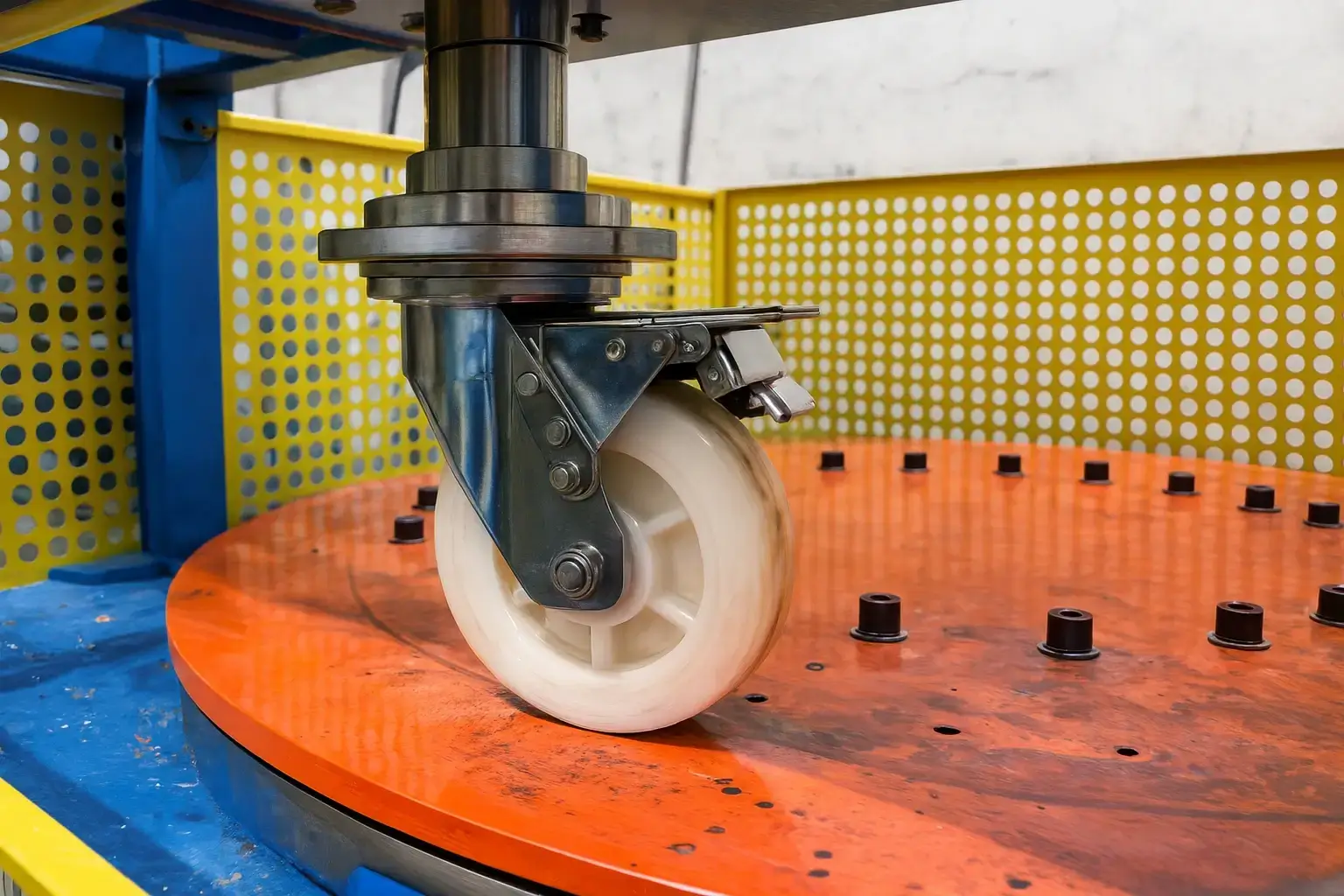

Dynamic load running test

Casters undergo dynamic load and rolling performance tests according to international standard to verify durability, stability, and long-term reliability.

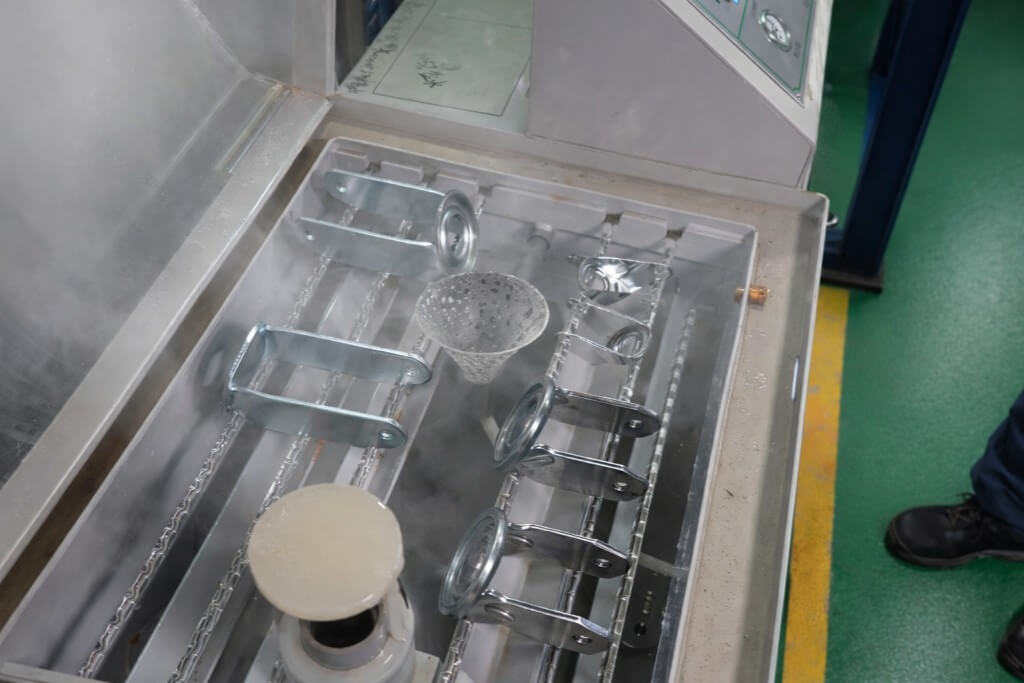

Salt spray test

Corrosion resistance is evaluated through salt spray testing to assess surface treatment durability and long-term performance in humid or aggressive environments.

Blanking and forming

Precision stamping and forming ensure structural strength, dimensional accuracy, and stable load-bearing performance from the very first production stage.

Mounting and assembly

Standardized assembly procedures and controlled setups ensure consistent specifications, secure fastening, and smooth swivel or rolling performance.

Testimonials

Let's Talk!

Tell us about your requirement, we typically reply within 24 hours

*We respect your privacy and all your information are protected.

DIRECT WHATSAPP

+86 18148886224

eric@wheelswaycaster.com